-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

Secondary Inductance: Tested at 10kHz, 0.1VRMS.

-

Current Rating: Peak current (50% duty cycle) through primary (1-2) to cause 40°C temperature rise at 25°C ambient.

-

SRF: Values are for reference only.

-

Flammability Standard: Meets UL 94V-0.

-

Meets RXT-2 Class F Insulation System (E169423).

-

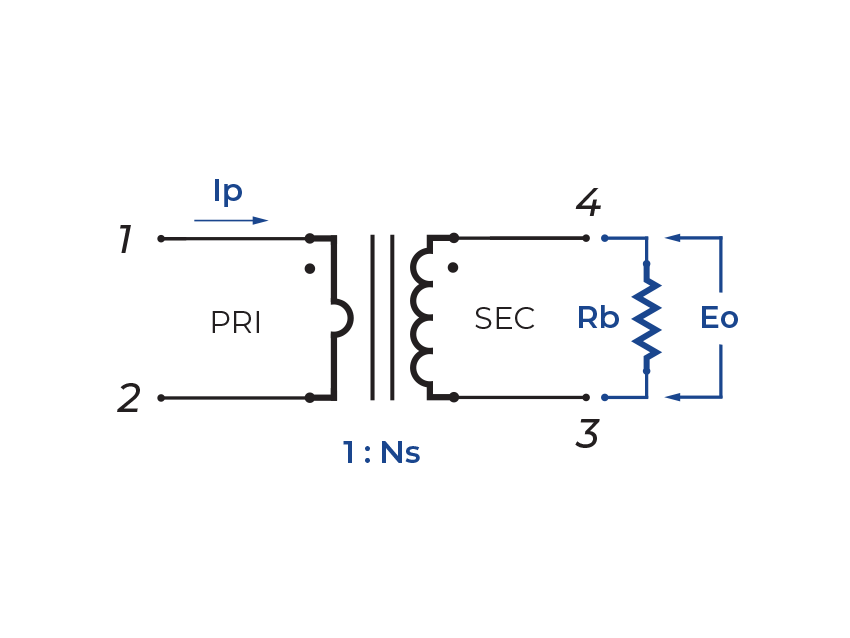

Terminating Resistor (RB): To calculate the value use the formula,

RB = EOTR/IP -

ET Product: The maximum ET is based upon a flux density of 3700 Gauss at 25°C. Suitable for bipolar applications only.

ET = EO/2f

EO = IPRB/TRWhereas,

EO = Output voltage (V) TR = Turns Ratio

RB = Term. Resistor (Ω) f = Frequency (Hz)

IP = Primary Current (A) -

PACKAGING

-

Reel Diameter: 13”

-

Reel Width: 16mm

-

Pieces/Reel: 1000

-

-

Compliance & Solutions:

-

Specifications subject to change without prior notice.

Selecting a turns ratio depends on the sense-voltage requirement of your controller, the expected primary current range, and the burden resistor value. Lower ratios (e.g., 1:50) are suited for higher-current rails where only modest sense voltage is needed, while higher ratios (e.g., 1:250) provide greater sense voltage — ideal for lower-current rails or higher-resolution sensing — provided the burden resistor and operating conditions conform to the ET-product and frequency limitations.

You should choose a burden resistor that produces enough sense voltage for accurate measurement while keeping the transformer within its rated ET-product and thermal limits. The datasheet provides calculation guidelines relating turns ratio, primary current, output voltage and frequency — use those to size the burden resistor correctly to prevent core saturation or signal distortion.

Yes. CT06 is well suited for use in current-mode control loops, average-current regulation, and over-current detection or protection circuits. Its combination of flexible turns ratios, 18 A current capability, high isolation, and SMT convenience makes it a versatile choice for many switching-power applications.

Yes — for best results, route the primary current path with minimal loop area, place the burden resistor close to the secondary pins, and ensure secondary and sense traces are kept short and separated from high dV/dt switching nodes. Good layout helps minimize noise coupling and ensures stable, accurate current sensing.

Yes. CT06 is designed for switch-mode current sensing, including pulsed or non-sinusoidal inductor or switch-node currents. Provided the waveform’s volt-seconds, duty cycle, burden resistor, and frequency remain within datasheet limits, CT06 will reproduce current waveforms reliably.

Yes — many variants of the CT06 Series feature a typical self-resonant frequency (SRF) around 1.5 MHz, which makes them suitable for high-frequency power supplies when properly burdened, filtered, and paired with a solid PCB layout.

CT06 offers 1,500 VAC primary-to-secondary isolation (Hi-Pot tested), giving safe separation between high-current primary circuits and low-voltage sensing or control circuits — suitable for a wide range of SMPS, POL, and embedded power applications where electrical isolation is required.

The CT06 Series supports operation from –40 °C up to +130 °C (ambient plus temperature rise), ensuring reliable performance across industrial, telecom, and embedded system environments.

The conductor carrying the current to be sensed should be routed through the CT06 primary. The secondary winding, together with the burden resistor, produces a scaled, isolated voltage proportional to the current. This allows the transformer to monitor inductor-leg, switch-node, or supply-rail currents without introducing insertion loss in the main current path.

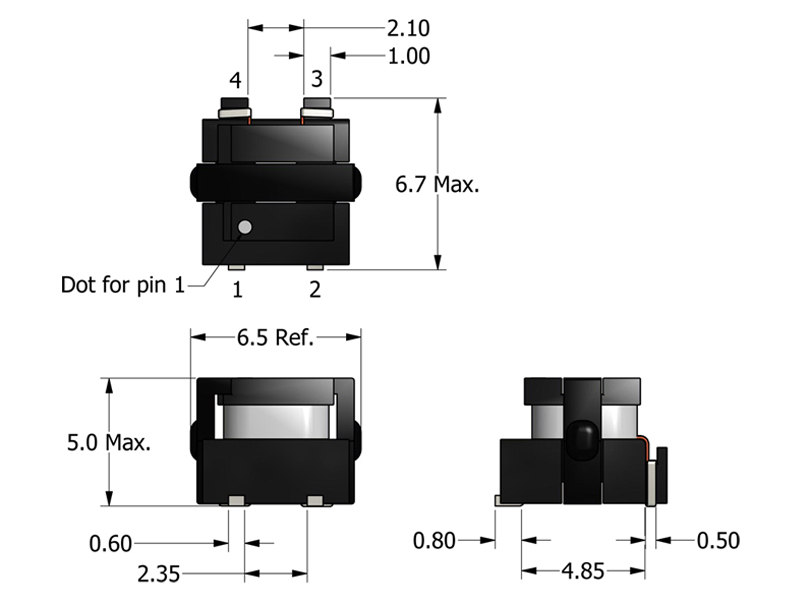

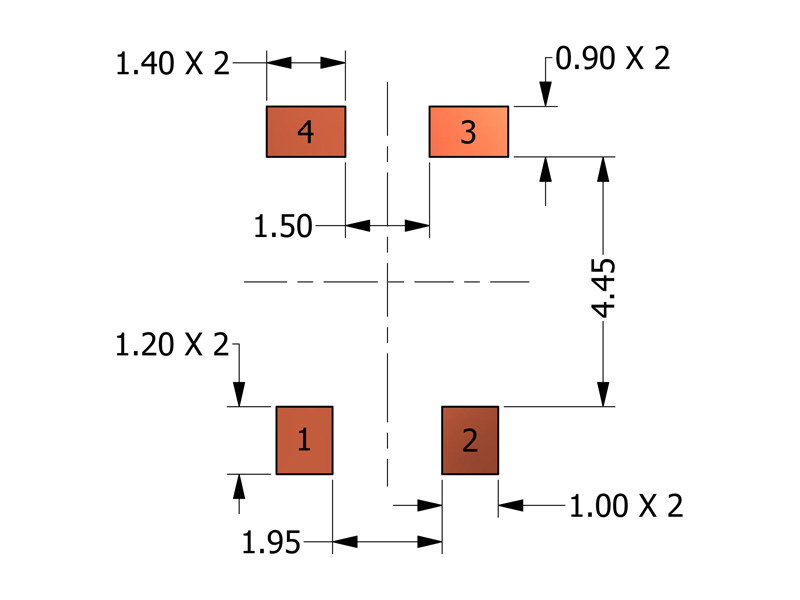

All documentation, including datasheets, mechanical drawings, recommended PCB layouts, and options to request SPICE or 3D CAD models, is available via the CT06 product page on ICE Components’ website. This facilitates easy integration into design, simulation, and manufacturing workflows.