-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

Secondary Inductance: Tested at 10kHz, 0.1 VRMS. CT05-1000 is tested @ 1kHz, 0.1VRMS.

-

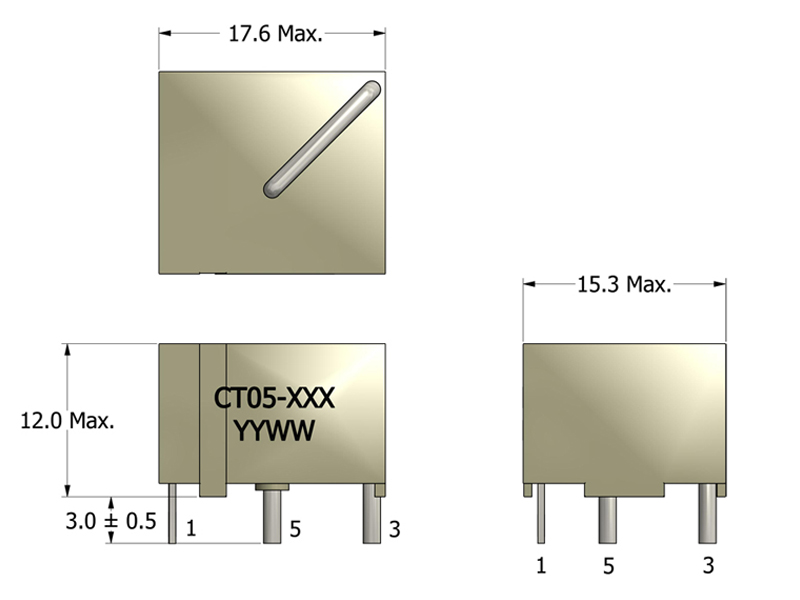

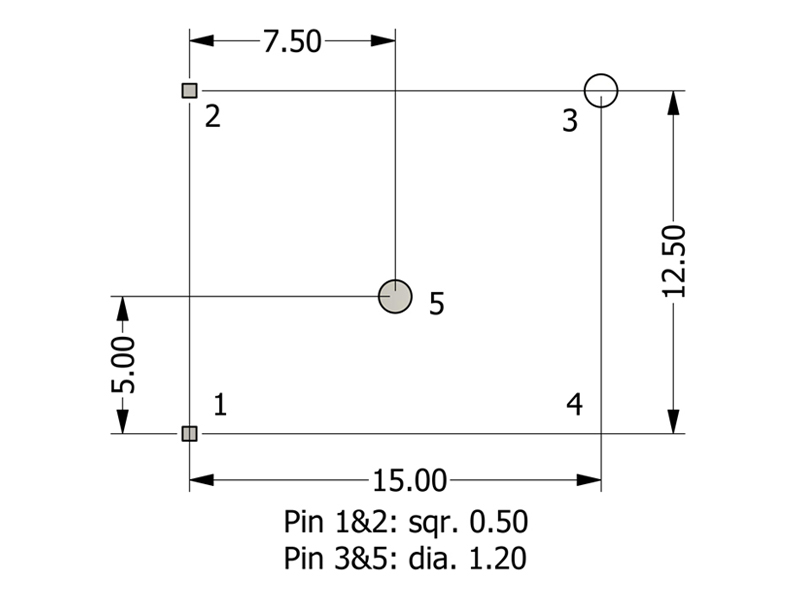

Primary DCR (3-5): 0.6 mΩ (Ref)

-

Current Rating: Peak current (50% duty cycle) through primary (3-5) to cause 40°C temperature rise at 25°C ambient.

-

SRF: Values are for reference only.

-

Flammability Standard: Meets UL 94V-0.

-

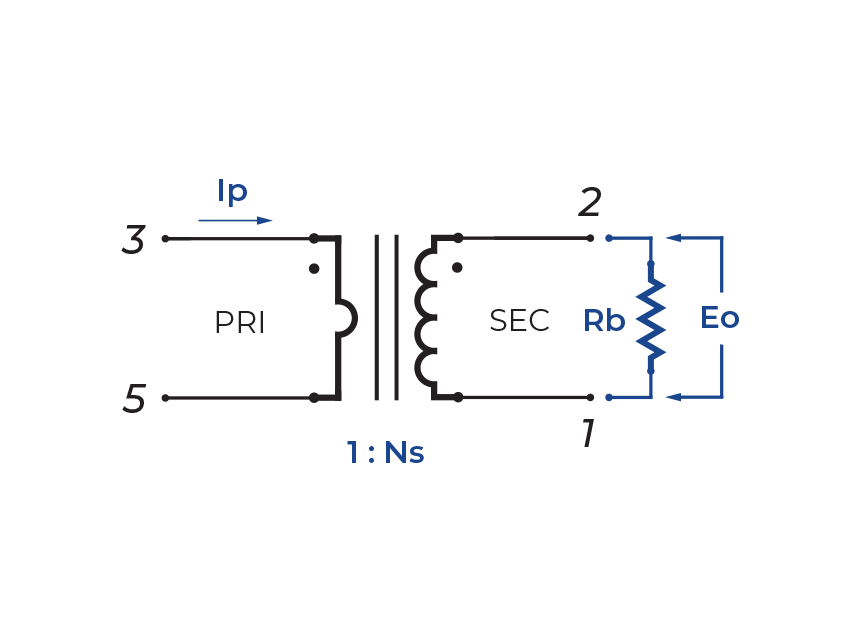

Terminating Resistor (RB): To calculate the value use the formula,

RB = EOTR/IP -

ET Product: The maximum ET is based upon a flux density of 1175 Gauss at 25°C. Suitable for bipolar applications only.

ET = EO/2f

EO = IPRB/TRWhereas,

EO = Output voltage (V) TR = Turns Ratio

RB = Term. Resistor (Ω) f = Frequency (Hz)

IP = Primary Current (A) -

PACKAGING

-

Pieces/Tray: 121

-

Trays/Box: 10

-

Pieces/Box: 1210

-

-

Compliance & Solutions:

-

Specifications subject to change without prior notice.

You should select a turns ratio based on the sense-voltage requirements of your controller or monitoring circuit, and the expected primary current. Lower ratios (1:50) suit higher-current rails with modest sense-voltage needs, while higher ratios (1:500 or 1:1000) generate larger sense voltages — useful for lower-current rails or where high resolution is needed. Always confirm that burden resistor selection and switching frequency keep flux-time (ET) within the transformer's rated limits.

Use a burden resistor that produces enough sense voltage for your measurement or controller input while keeping the transformer in safe operating limits. The datasheet provides an ET-product formula and maximum ET threshold; selecting R_B using ET = (Ip × Rb / TR) / (2·f) helps ensure accurate waveform reproduction without saturating the core.

Yes. CT05 supports current-mode control loops, over-current detection, load-drop monitoring, and general current-sense tasks in AC/DC and DC/DC converters. Its combination of high current capacity, isolation, and flexible turns ratios makes it a good candidate for these applications.

Because CT05 is a through-hole transformer with a bar-primary design, ensure the primary conductor or PCB trace is rated for the intended current, and secondary traces plus the burden resistor are kept short and routed away from high-noise switching nodes. Good layout reduces parasitic noise and improves measurement accuracy.

Yes. CT05 is designed for switch-mode converter current sensing and can handle pulsed or non-sinusoidal waveforms, provided the duty cycle, ET-product, and burden resistor are appropriately designed according to the datasheet guidelines.

CT05 is Hi-Pot tested to 4000 VAC primary-to-secondary isolation. This makes it suitable for applications requiring safe isolation between the high-current primary path and low-voltage sensing or control circuits, such as AC mains front-ends or isolated DC/DC converters.

The CT05 Series operates from –40 °C to +130 °C ambient (or ambient + temperature rise depending on load). This ensures reliability in industrial, telecom, and other demanding environments under varying thermal conditions.

The current to be monitored is passed through the transformer’s primary path (bar-style or PCB trace), while the secondary winding, together with the burden resistor, delivers a scaled, isolated voltage proportional to that current. This configuration supports accurate sensing of power-rail currents, inductor currents, or supply lines without inserting a shunt resistor in the primary path.

At high switching frequencies, factors such as secondary inductance, burden resistor value, PCB parasitics, and the transformer’s SRF (self-resonant frequency) affect accuracy. Designers should ensure the burden and layout design maintain good waveform fidelity and stay within the ET-product and the component’s frequency rating.

All relevant documentation — including datasheet, mechanical drawings, recommended PCB footprint, and requests for SPICE or 3D CAD models — are available via the CT05 product page on ICE Components’ website. This ensures easy integration into design, simulation, and layout workflows.