-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

Secondary Inductance: Tested at 10kHz, 1VRMS.

-

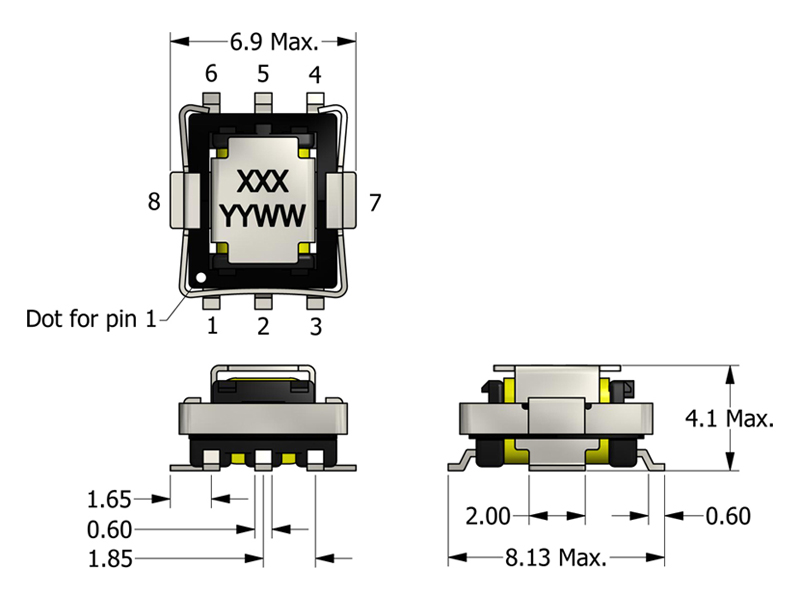

Primary DCR (8-7): 0.4 mΩ (Ref)

-

Current Rating: Peak current (50% duty cycle) through primary (8-7) to cause 40°C temperature rise at 25°C ambient.

-

SRF: Values are for reference only.

-

Flammability Standard: Meets UL 94V-0.

-

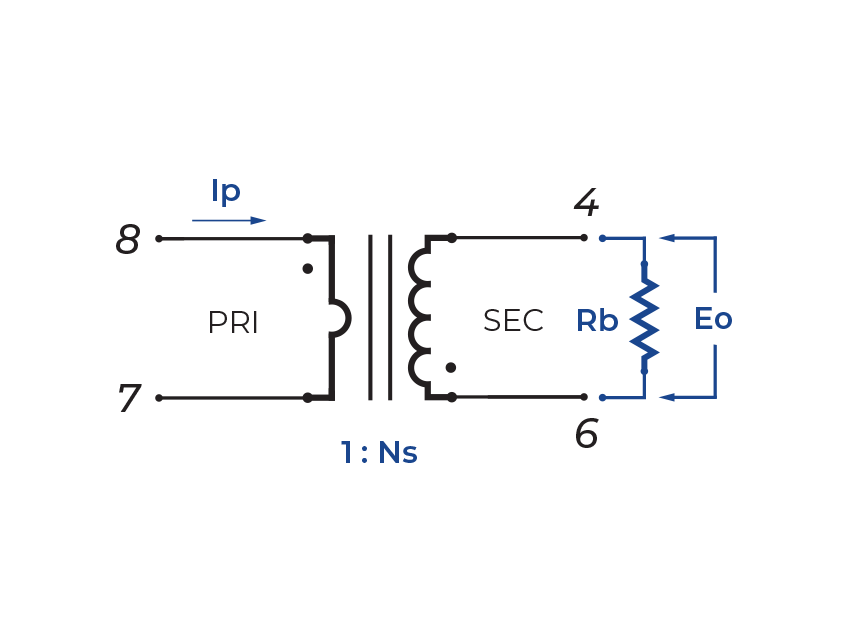

Terminating Resistor (RB): To calculate the value use the formula,

RB = EOTR/IP -

ET Product: The maximum ET is based upon a flux density of 3700 Gauss at 25°C. Suitable for bipolar applications only.

ET = EO/2f

EO = IPRB/TRWhereas,

EO = Output voltage (V) TR = Turns Ratio

RB = Term. Resistor (Ω) f = Frequency (Hz)

IP = Primary Current (A) -

PACKAGING

-

Reel Diameter: 13”

-

Reel Width: 16mm

-

Pieces/Reel: 1200

-

-

Compliance & Solutions:

-

Specifications subject to change without prior notice.

Choose the turns ratio based on the sense-voltage requirements of your controller and the expected primary current range. Lower ratios (1:50) are suited for higher-current rails, while higher ratios (1:125) generate more output voltage for lower-current sensing. Ensure the chosen combination complies with the ET-product and burden resistor recommendations from the datasheet.

Select a burden resistor that provides adequate sense voltage while keeping the transformer within its ET and thermal limits. The datasheet’s calculation guidance helps ensure the resistor value supports accurate waveform reproduction without overloading the transformer or controller input.

Yes. CT04 works effectively in current-mode control loops, average-current regulation, and over-current detection. When optimally paired with appropriate burden and filtering, it generates a clean, isolated sense signal compatible with standard SMPS controllers.

For best performance, route the primary current path with minimal loop area, keep the burden resistor close to the transformer’s secondary pins, and avoid placing high dV/dt switching nodes near the sense lines. These practices help ensure signal clarity and reduce coupling noise.

Yes. CT04 is designed for switch-mode current sensing and can accurately measure pulsed or triangular inductor currents as long as operating conditions remain within ET-product and burden resistor limits.

Yes. With typical self-resonant frequencies around 1 MHz (varying by part number), CT04 supports many high-frequency SMPS applications. Proper burden value, filtering, and PCB layout help maintain waveform accuracy approaching the upper frequency range.

CT04 provides 500 VAC primary-to-secondary isolation, offering safe electrical separation between the sensed current path and low-voltage monitoring circuitry.

The CT04 Series is rated for –40 °C to +130 °C, enabling stable operation in demanding industrial, telecom, and high-density power environments.

The sensed current is routed through the primary pins of the transformer. The secondary winding, combined with the burden resistor, generates a scaled and isolated voltage proportional to the measured current for use by the controller or monitoring circuit.

The CT04 product page provides downloadable datasheets, mechanical drawings, layout guidance, and options to request SPICE or 3D CAD models for integration into design workflows.