-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

Secondary Inductance: Tested at 10kHz, 0.1VRMS.

-

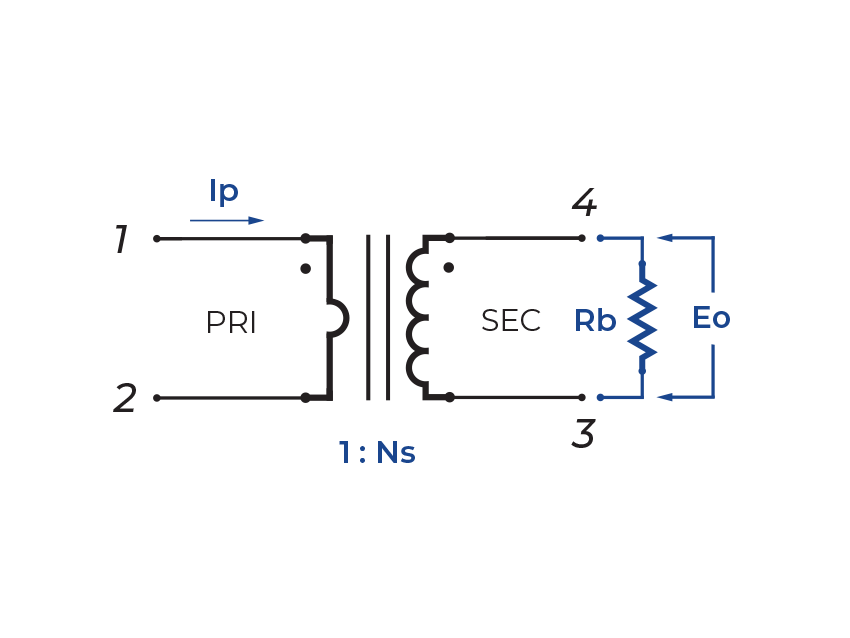

Current Rating: Peak current (50% duty cycle) through primary (1-2) to cause 40°C temperature rise at 25°C ambient.

-

SRF: Values are for reference only.

-

Flammability Standard: Meets UL 94V-0.

-

Terminating Resistor (RB): To calculate the value use the formula,

RB = EOTR/IP -

ET Product: The maximum ET is based upon a flux density of 3700 Gauss at 25°C. Suitable for bipolar applications only.

ET = EO/2f

EO = IPRB/TRWhereas,

EO = Output voltage (V)

TR = Turns Ratio

RB = Term. Resistor (Ω)

f = Frequency (Hz)

IP = Primary Current (A) -

PACKAGING

-

Reel Diameter: 13”

-

Reel Width: 16 mm

-

Pieces/Reel: 1000

-

-

Compliance & Solutions:

-

Specifications subject to change without prior notice.

Selecting the turns ratio for CT02 depends on the sense-voltage range your controller expects, the burden resistor value, and the converter’s intended current range. A lower ratio like 1:50 yields a smaller sense voltage (and lower burden resistor wattage), whereas higher ratios (e.g., 1:250) produce larger sense voltage — useful for low-current rails or high-precision sensing — but must be balanced against burden dissipation, ET-product limits, and thermal performance.

You should choose a burden resistor that yields sufficient sense voltage for accurate detection but keeps the transformer within its ET-product and thermal limits. Using the formula from the datasheet (RB = E_O·TR / I_P), designers can calculate resistor values appropriate for their primary current and turns ratio to ensure reliable waveform reproduction without saturation or overheating.

Yes — CT02 is designed for AC/DC, DC/DC and POL converter topologies and works well in current-mode, average-current, or over-current detection circuits, as long as the burden resistor and filtering network are dimensioned properly to match the controller’s input requirements.

Yes. For best results, route the primary current path with minimal loop area, place the burden resistor close to the secondary winding, and avoid routing high dV/dt switching traces directly underneath or adjacent to the transformer. These practices help maintain signal integrity, reduce noise coupling, and improve measurement stability

Yes — CT02 is suited for switch-mode converter current sensing, including pulsed inductor currents or non-sinusoidal waveforms. As long as the design stays within the ET-product and thermal limits indicated in the datasheet, and burden/filtering are properly chosen, CT02 will reproduce current waveforms accurately.

In most cases no additional metal shielding is needed. A well-implemented ground plane under the transformer and proper trace spacing typically provide sufficient noise immunity even in high-switching-frequency or high dV/dt environments.

Yes. With its range of turns ratios, isolation, and SMT form factor, CT02 integrates smoothly with standard current-mode, average-current, or protection-type SMPS controllers, provided burden and layout guidelines are followed.

The conductor being measured should be routed through the CT02 primary (pins 1–2), while the secondary, together with the burden resistor, generates a scaled, isolated sense voltage. This configuration supports monitoring of inductor currents, switch-node currents, or power-rail currents — depending on your design.

Accuracy depends on burden resistor value, transformer parasitics (leakage inductance, capacitance), PCB parasitics, and input filtering. Keeping secondary traces short, using proper burden values, and avoiding capacitive coupling to noisy nodes helps preserve waveform fidelity at high switching frequencies near the transformer’s SRF rating.

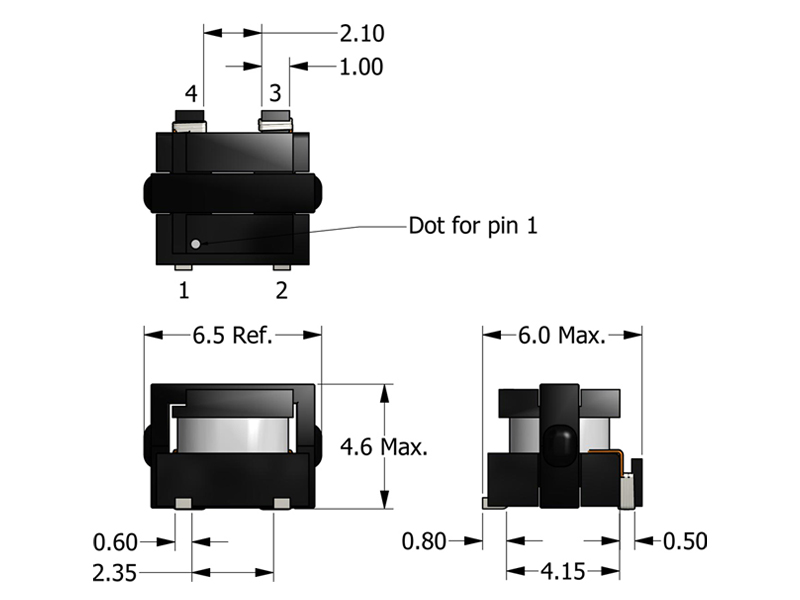

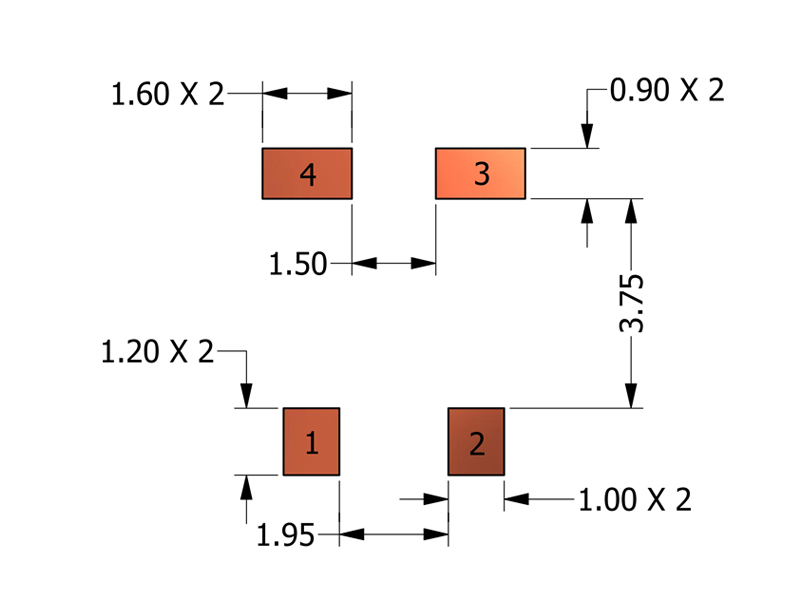

All documentation — including datasheet, mechanical drawings, recommended PCB layout drawings and options for SPICE or 3D CAD files — are available on the ICE Components CT02 product page.