- Home

- Inductors

- VRM/VRD Power Inductors

- VRM/VRD Inductors

VRM/VRD Inductors

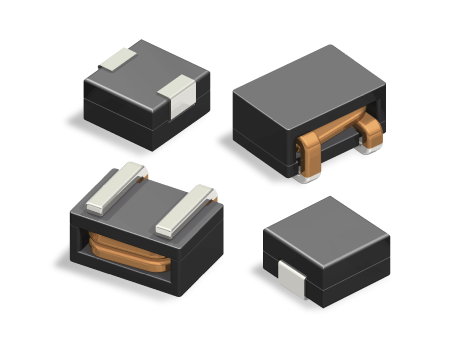

ICE Components’ VRM/VRD Power Inductors provide high-efficiency, low-loss magnetic performance for modern voltage regulator modules (VRMs), voltage regulator-down (VRD) converters, and point-of-load (POL) power stages. Engineered for high-current, fast-transient digital loads such as CPUs, GPUs, ASICs, memory modules, and server processors, these inductors deliver stable inductance, low DCR, and strong thermal behavior in compact footprints.

Available in a range of inductance values, sizes, and current ratings, the VRM/VRD series supports high-density multi-phase buck converters and advanced motherboard-level architectures. Their optimized power handling, mechanical stability, and low EMI characteristics make them ideal for enterprise hardware, telecom systems, embedded designs, and high-performance computing platforms.

Key Features

- Low-DCR construction optimized for high-current VRM rails

- Broad inductance and current options for flexible power stages

- High current capability supporting multi-phase buck systems

- Compact footprint choices for dense PCB layouts

- Magnetic design minimizing losses and improving efficiency

- SMT or THT packages compatible with automated assembly

APPLICATIONS

- CPU and GPU VRM/VRD power stages

- Multi-phase buck converters in servers and high-performance computing

- Point-of-load (POL) modules on motherboards and embedded systems

- Telecom, networking, and data center power rails

- High-efficiency DC/DC converters in compact power supplies

- CPU and GPU VRM/VRD power stages

- Multi-phase buck converters in servers and high-performance computing

- Point-of-load (POL) modules on motherboards and embedded systems

- Telecom, networking, and data center power rails

- High-efficiency DC/DC converters in compact power supplies

| Part Number |

Competition | Ls(nH) | ISAT @125°C (ADC) |

ISAT @25°C (ADC) |

DCR (mΩ) |

Footprint (mm) |

Height (mm) |

Shielded | Samples Available |

|---|---|---|---|---|---|---|---|---|---|

| IN06090 | 600 | 26.0 | 1.26 | 10.6 x 8.7 | 6.00 | N |  |

||

| IN08074 | 8500 | 11.0 | 7.8 | 11.20 | 15.2 x 13.0 | 10.00 | Y |  |

|

| IN08075 | 10000 | 11.0 | 7.6 | 7.50 | 18.2 x 13.3 | 10.00 | Y |  |

|

| IN06092 | 300 | 30.0 | 25.0 | 0.48 | 11.0 x 8.0 | 7.00 | N |  |

|

| IN06073-1 | 150 | 58.0 | 0.22 | 10.5 x 10.0 | 7.50 | N |  |

||

| IN08082 | 840 | 39.0 | 30.0 | 1.30 | 12.4 x 12.5 | 6.90 | Y |  |

|

| IN08087 | 1400 | 20.5 | 16.0 | 3.40 | 10.4 x 8.7 | 5.55 | Y |  |

|

| IN08091 | 215 | 50.0 | 39.0 | 0.29 | 10.4 x 8.0 | 7.50 | N |  |

|

| IN08097 | 710 | 20.0 | 16.0 | 2.10 | 8.0 x 7.7 | 5.50 | Y |  |

|

| IN08106 | 710 | 24.0 | 19.0 | 3.00 | 8.0 x 7.7 | 5.50 | Y |  |

|

| IN06155 | 1000 | 19.0 | 2.30 | 10.0 x 8.0 | 5.60 | Y |

|

||

| IN06111 | 380 | 46.0 | 40.0 | 0.65 | 10.3 x 12.0 | 7.00 | Y |  |

|

| IN08114 | 16000 | 4.5 | 3.5 | 13.50 | 10.3 x 8.0 | 8.00 | Y |  |

|

| IN08122 | 600 | 50.0 | 37.0 | 1.30 | 12.4 x 12.5 | 5.70 | Y |  |

|

| IN08124 | 320 | 48.0 | 40.0 | 0.45 | 13.1 x 13.0 | 8.00 | N |  |

|

| IN08127 | 980 | 13.0 | 11.0 | 1.90 | 10.0 x 8.0 | 4.35 | Y |  |

|

| IN06088 | 1000 | 16.0 | 2.50 | 10.0 x 8.0 | 4.80 | Y |  |

||

| IN08080 | 150 | 34.0 | 27.0 | 0.26 | 9.0 x 7.0 | 4.00 | N |  |

|

| IN08130 | 780 | 41.0 | 30.0 | 1.40 | 12.4 x 12.5 | 6.90 | Y |  |

|

| IN08132 | 12500 | 5.8 | 4.5 | 13.50 | 10.3 x 8.0 | 8.00 | Y |  |

|

| IN08133 | 100 | 85.0 | 75.0 | 0.80 | 10.0 x 8.0 | 4.25 | Y |  |

|

| ICA2194 | 70 | 35.0 | 0.43 | 7.2 x 6.7 | 3.00 | N |  |

||

| IN06017 | 380 | 50.0 | 42.0 | 0.55 | 10.3 x 12.0 | 7.80 | Y |  |

|

| IN06073-2 | 120 | 72.0 | 0.22 | 10.5 x 10.0 | 7.50 | N |  |

||

| IN06073-3 | 210 | 50.0 | 42.0 | 0.22 | 10.5 x 10.0 | 7.50 | N |  |

|

| IN08078 | 300 | 34.0 | 25.0 | 0.29 | 11.0 x 7.2 | 7.50 | N |  |

|

| IN08112 | 1000 | 19.0 | 15.0 | 2.00 | 10.4 x 8.7 | 5.60 | Y |  |

|

| IN08147 | 380 | 45.0 | 38.0 | 0.43 | 10.3 x 12.8 | 8.40 | Y |  |

|

| IN08128 | 150 | 75.0 | 61.0 | 0.29 | 11.0 x 7.2 | 7.60 | N |  |

|

| IN08131 | 1500 | 17.0 | 14.0 | 2.40 | 10.3 x 8.0 | 6.70 | Y |  |

|

| IN08134 | 1000 | 34.0 | 24.0 (@ +120°C) | 2.90 | 15.0 x 14.5 | 4.30 | Y |  |

|

| IN09004 | 1000 | 34.0 | 27.0 | 3.00 | 10.4 x 11.2 | 8.00 | Y |  |

|

| IN06117 | 240 | 50.0 | 45.0 | 0.17 | 13.5 x 13.0 | 7.10 | N |  |

|

| IN08137 | 800 | 45.0 | 36.0 | 1.40 | 14.3 x 12.0 | 7.50 | Y |  |

|

| IN08141 | 510 | 17.0 | 14.0 | 0.47 | 10.9 x 7.2 | 7.50 | N |  |

|

| IN08144 | 59PR9884 (ViTec) |

470 | 30.0 | 24.0 | 0.50 | 11.2 x 11.2 | 9.00 | N |  |

| IN08145 | 59PR8902 (ViTec) |

260 | 60.0 | 48.0 | 0.17 | 13.5x 13.0 | 8.00 | N |  |

| IN08146 | 400 | 60.0 | 50.0 | 0.52 | 14.3 x 12.8 | 8.50 | Y |  |

|

| IN09003 | 220 | 63.0 | 54.0 | 0.17 | 13.5 x 13.0 | 7.50 | N |  |

|

| IN09011 | 380 | 42.0 | 35.0 | 0.65 | 10.3 x 11.6 | 6.30 | Y |  |

|

| IN06130 | 660 | 27.0 | 22.0 | 1.15 | 10.3 x 8.0 | 6.20 | Y |  |

|

| IN09020 | 1000 | 30.0 | 24.0 | 2.00 | 10.4 x 11.5 | 9.80 | N |  |

|

| IN09029 | 980 | 12.0 | 9.5 | 2.30 | 10.0 x 8.0 | 3.50 | Y |  |

|

| IN09038 | 15000 | 8.8 | 22.00 | 13.8 x 13.0 | 6.60 | Y |  |

||

| IN09044 | 59PR9883 (ViTec) |

325 | 44.0 | 35.0 | 0.50 | 11.2 x 11.2 | 9.10 | N |  |

| IN09057 | 59PR9871N (ViTec) |

120 | 87.0 | 73.0 | 0.29 | 11.0 x 7.2 | 7.60 | N |  |

| IN09059 | 1500 | 40.0 | 31.0 | 2.80 | 14.4 x 12.0 | 8.50 | Y |  |

|

| IN09071 | 2000 | 10.0 | 5.80 | 7.7 x 7.1 | 5.20 | Y |  |

||

| IN09106 | 500 | 56.0 | 46.0 | 0.95 | 12.4 x 11.0 | 8.00 | 8.00 |  |

|

| IN09141 | 8800 | 4.8 | 4.0 (@ +100°C) | 20.00 | 10.4 x 10.4 | 5.60 | Y |  |

|

| IN10034 | 410 | 42.0 | 35.0 | 0.62 | 10.4 x 13.0 | 30 | N |  |

|

| IN10035 | 185 | 34.0 | 31.0 (@ +100°C) | 0.21 | 9.4 x 7.0 | 5.50 | N |  |

|

| IN06144 | 40 | 40.0 | 0.32 | 4.0 x 4.0 | 4.00 | N |  |

||

| IN10114 | 240 | 35.0 | 42.0 | 0.55 | 10.9 x 8.1 | 6.05 | Y |  |

|

| IN10132 | 320 | 40.0 | 57.0 | 0.17 | 13.6 x 13.0 | 8.80 | N |  |

|

| IN10154 | 250 | 57.0 | 70.0 | 0.17 | 13.6 x 13.0 | 8.80 | N |  |

|

| IN11013 | 250 | 62.0 | 78.0 | 0.25 | 13.5 x 13.0 | 9.50 | N |  |

|

| IN11015 | 220 | 37.0 | 47.0 | 0.52 | 10.6 x 11.0 | 8.10 | Y |  |

|

| IN11026 | 2700 | 8.0 | 11.0 | 4.60 | 10.4 x 10.4 | 5.25 | Y |  |

|

| IN11043 | 85 | 35.0 | 41.0 | 0.60 | 6.9 x 6.8 | 4.00 | N |  |

|

| IN09101 | 1000 | 60.0 | 1.00 | 14.2 x 13.2 | 6.20 | Y |  |

||

| IN12097 | 150 | 57.0 | 48.0 | 0.20 | 5.0 x 10.4 | 10.00 | Y |  |

|

| IN06156 | 59P987x (ViTec) |

150 | 64.0 | 55.0 | 0.47 | 11.0 x 7.2 | 7.50 | N |  |

| IN07002 | 620 | 27.0 | 22.0 | 0.60 | 10.4 x 13.0 | 5.60 | Y |  |

|

| IN07004 | 660 | 28.0 | 25.0 | 1.25 | 10.3 x 8.1 | 6.60 | Y |  |

|

| IN07023 | 900 | 24.0 | 1.00 | 13.0 x 11.0 | 6.00 | Y |  |

||

| IN07028 | 85 | 75.0 | 57.0 | 0.55 | 7.6 x 7.4 | 7.00 | N |  |

|

| IN07037 | 4600 | 32.0 | 32.0 | 4.30 | 13.7 x 13.1 | 7.50 | Y |  |

|

| IN07038 | 4700 | 12.0 | 8.5 | 9.00 | 13.0 x 13.0 | 5.80 | Y |  |

|

| IN07039 | 3200 | 15.0 | 11.0 | 6.20 | 13.0 x 13.0 | 5.80 | Y |  |

|

| IN07049 | 59PR9052 (ViTec) |

500 | 19.0 | 15.0 | 50 | 8.0 x 7.7 | 4.50 | Y |  |

| IN07056 | 380 | 46.0 | 40.0 | 0.65 | 10.4 x 13.0 | 6.00 | Y |  |

|

| IN07066 | 40 | 8.0 | 0.24 | 4.1 x 4.0 | 2.00 | N |  |

||

| IN07205 | 1000 | 19.0 | 16.0 | 2.30 | 9.5 x 8.0 | 6.00 | Y |  |

|

| IN07200 | 500 | 60.0 | 45.0 | 1.30 | 12.4 x 10.4 | 12.4 x 10.4 | 6.60 | Y |  |

| IN07196 | 50 | 80.0 | 70.0 | 0.30 | 10.0 x 8.1 | 4.05 | Y |  |

|

| IN07185 | 7200 | 13.5 | 7.00 | 13.7 x 13.1 | 7.50 | Y |  |

||

| IN07184 | 125 | 80.0 | 67.0 | 0.29 | 10.9 x 7.2 | 7.50 | N |  |

|

| IN07182 | 1300 | 40.0 | 31.0 | 2.30 | 14.3 x 12.0 | 7.50 | Y |  |

|

| IN07180 | 33000 | 8.0 | 2.70 | 27.9 x 28.0 | 16.60 | Y |  |

||

| IN07176 | 510 | 45.0 | 36.0 | 0.60 | 14.3 x 12.3 | 8.00 | Y |  |

|

| IN07175 | 400 | 60.0 | 48.0 | 0.60 | 14.3 x 12.3 | 8.00 | Y |  |

|

| IN07159 | 30 | 65.0 | 52.0 | 0.32 | 4.2 x 4.0 | 4.10 | N |  |

|

| IN07158 | 105 | 50.0 | 42.0 | 0.30 | 10.0 x 8.1 | 3.80 | Y |  |

|

| IN07155 | 320 | 72.0 | 60.0 | 0.60 | 14.3 x 12.3 | 8.00 | Y |  |

|

| IN07152 | 230 | 41.0 | 33.0 | 0.29 | 10.9 x 7.2 | 7.50 | N |  |

|

| IN07151 | 150 | 63.0 | 54.0 | 0.29 | 10.9 x 7.2 | 7.60 | N |  |

|

| IN07067 | 660 | 45.0 | 36.0 | 1.30 | 12.4 x 10.4 | 6.50 | Y |  |

|

| IN07075 | 59PR8971 (ViTec) |

1200 | 13.5 | 10.6 | 4.00 | 8.0 x 7.7 | 4.35 | Y |  |

| IN07085 | 59PR32-102 (ViTec) |

1000 | 33.0 | 26.0 | 1.50 | 10.4 x 13.0 | 7.50 | Y |  |

| IN07087 | 1000 | 35.0 | 1.15 | 13.1 x 11.0 | 6.30 | Y |  |

||

| IN07088 | 1000 | 25.0 | 1.25 | 13.0 x 11.0 | 6.00 | Y |  |

||

| IN07089 | 9000 | 4.4 | 32.00 | 7.0 x 7.0 | 4.55 | Y |  |

||

| IN07090 | 6000 | 5.3 | 19.00 | 7.0 x 7.0 | 5.00 | Y |  |

||

| IN07101 | 410 | 57.0 | 48.0 | 0.80 | 14.3 x 12.3 | 7.00 | Y |  |

|

| IN07101 | 410 | 57.0 | 48.0 | 0.80 | 14.3 x 12.3 | 7.00 | Y |  |

|

| IN07116 | 59PR31-721 (ViTec) |

720 | 35.0 | 28.0 | 1.10 | 10.4 x 13.0 | 6.00 | Y |  |

| IN07119 | 200 | 48.0 | 41.0 | 0.47 | 11.1 x 8.0 | 7.50 | N |  |

|

| IN07121 | 1450 | 13.0 | 9.50 | 1.25 | 10.3 x 8.0 | 6.50 | Y |  |

|

| IN07122 | 2000 | 13.5 | 9.5 | 2.40 | 10.3 x 8.0 | 6.65 | Y |  |

|

| IN06104-1 | 330 | 28.0 | 22.0 | 0.50 | 10.5 x 8.9 | 5.00 | Y |  |

|

| IN06114 | 59PR9873 (ViTec) |

220 | 41.0 | 31.0 | 0.47 | 11.0 x 7.2 | 7.50 | N |  |

| IN06128 | 59P9891 (ViTec) |

1000 | 27.0 | 1.65 | 14.0 x 9.0 | 10.50 | Y |  |

|

| IN06133 | 70 | 55.0 | 45.0 | 0.27 | 7.2 x 6.7 | 4.96 | N |  |

|

| IN06143 | 22 | 70.0 | 0.32 | 4.0 x 4.0 | 4.10 | N |  |

||

| IN06146 | 59PR51-700 (ViTec) |

70 | 85.0 | 69.0 | 0.55 | 7.6 x 7.4 | 7.00 | N |  |

| IN07001 | 95 | 40.0 | 32.0 | 0.27 | 7.2 x 6.7 | 4.96 | N |  |

|

| IN07003 | 400 | 40.0 | 33.0 | 0.60 | 10.4 x 13.0 | 5.00 | Y |  |

|

| IN07013 | 59PR65-650 (ViTec) |

65 | 24.0 | 0.32 | 4.0 x 4.0 | 4.00 | N |  |

|

| IN07024 | 180 | 41.0 | 32.0 | 0.40 | 11.0 x 8.0 | 4.90 | N |  |

|

| IN07195 | 3600 | 10.5 | 8.5 | 6.30 | 10.0 x 8.0 | 7.00 | Y |  |

|

| IN08006 | 6000 | 30.0 | 21.0 | 3.60 | 23.8 x 21.0 | 13.60 | Y |  |

|

| IN08022 | 1000 | 33.0 | 26.0 | 1.50 | 10.4 x 11.4 | 8.00 | Y |  |

|

| IN08032 | 220 | 48.0 | 40.0 | 0.32 | 12.0 x 8.0 | 7.90 | N |  |

|

| IN08034 | 5000 | 9.0 | 6.5 | 6.80 | 10.3 x 8.0 | 6.65 | Y |  |

|

| IN08035 | 6400 | 7.0 | 5.0 | 6.80 | 10.3 x 8.0 | 6.65 | Y |  |

|

| IN08037 | 770 | 38.0 | 27.0 | 1.30 | 12.4 x 12.5 | 5.70 | Y |  |

|

| IN08041 | 2400 | 30.0 | 23.0 | 4.50 | 12.4 x 10.4 | 7.80 | Y |  |

|

| IN08046 | 1000 | 8.5 | 16.00 | 7.0 x 6.3 | 2.70 | Y |  |

||

| IN08048 | 280 | 33.0c | 25.0 | 0.29 | 10.9 x 7.2 | 7.50 | N |  |

|

| IN08050 | 680 | 21.0 | 16.0 | 1.20 | 10.5 x 9.4 | 5.80 | Y |  |

|

| IN08052 | 5900 | 7.5 | 5.5 | 6.80 | 10.3 x 8.0 | 6.65 | Y |  |

|

| IN08057 | 120 | 80.0 | 70.0 | 0. 47 | 10.9 x 7.2 | 7.50 | N |  |

|

| IN08069 | 200 | 21.0 | 17.0 | 0.86 | 7.2 x 6.7 | 3.00 | N |  |

|

| IN08070 | 59PR9873N (ViTec) |

220 | 47.0 | 39.0 | 0.29 | 11.0 x 7.2 | 7.50 | N |  |