LP06 Series

High-Current, Low-EMI, Surface-Mount Inductors

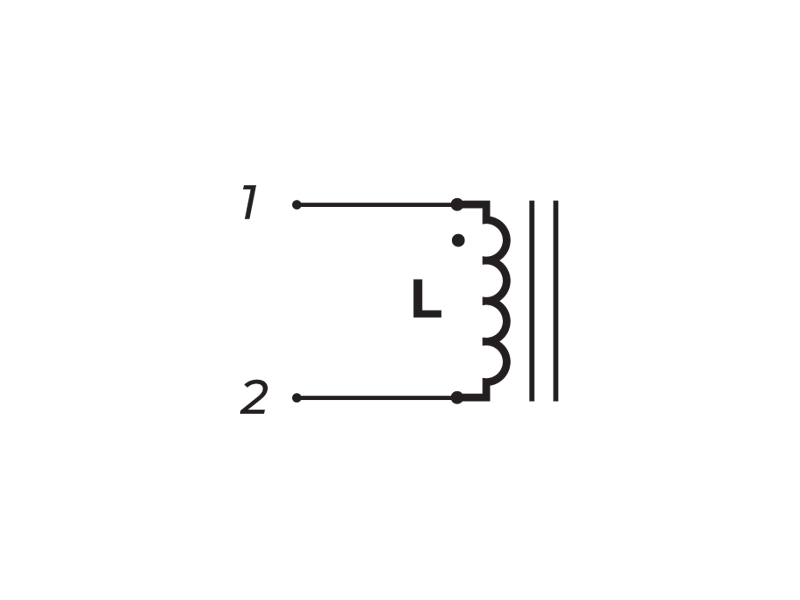

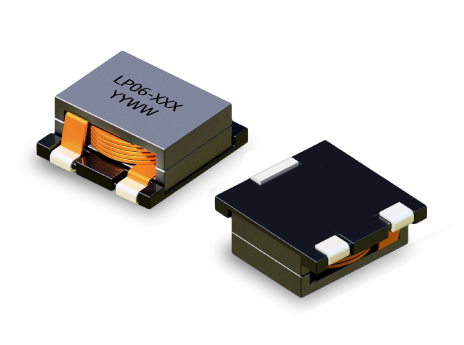

The LP06 Series surface-mount (SMT) high-current, low-EMI inductors deliver robust, efficient power delivery for DC/DC converters, VRMs, and power-rail supply stages. Offering inductance values from 100 nH upward (various models) and a saturation current rating up to 75 A, LP06 supports demanding power rails where high current and stable performance under varying load are required.

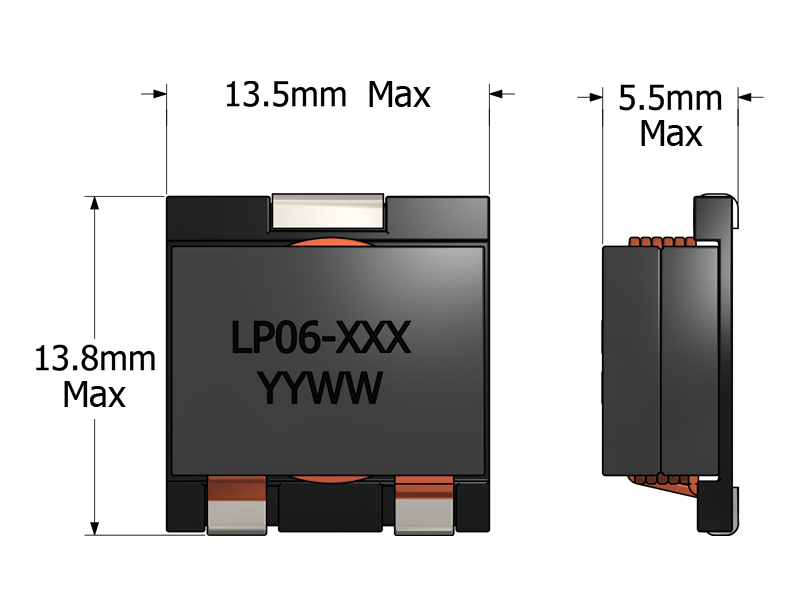

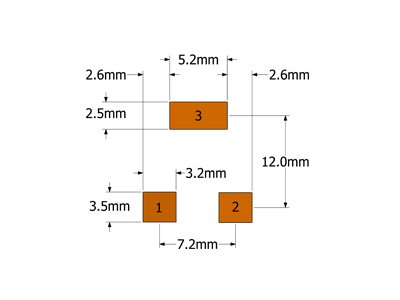

With a compact footprint of 13.5 × 13.8 mm (max) and a profile height of 5.5 mm (max), LP06 is designed for surface-mount pick-and-place mounting, enabling dense PCB layouts while maintaining high current capability and reduced EMI — ideal for servers, telecom, embedded systems, and high-power DC/DC modules.

Key Features

- Footprint 13.5 × 13.8 mm with 5.5 mm height for compact layouts

- Saturation rating up to 75 A for high-current power rails

- Inductance options from 100 nH to 7200 nH for flexible filtering

- Supports switching frequencies up to 1 MHz for modern converter stages

- Low-DCR winding improving efficiency under load

- Magnetically shielded construction reducing EMI

- SMT package supporting automated pick-and-place assembly

APPLICATIONS

- VRMs and POL converters in server and embedded systems

- High-current DC/DC stages for core and auxiliary power rails

- Low-EMI power modules using magnetically shielded inductors

- Rail filtering and output choke in compact power supplies

- Dense PCB layouts needing efficient SMT inductors

- Industrial and telecom equipment requiring stable high-current magnetics

- VRMs and POL converters in server and embedded systems

- High-current DC/DC stages for core and auxiliary power rails

- Low-EMI power modules using magnetically shielded inductors

- Rail filtering and output choke in compact power supplies

- Dense PCB layouts needing efficient SMT inductors

- Industrial and telecom equipment requiring stable high-current magnetics

Electrical Specifications @ 25°C - Operating Temperature Range1: -40°C to +130°C

Part Number

Inductance2

(nH, ±10%)

DCR (mΩ, Typ.)

ISAT3(A)

IDC4 (A)

Part Number

ISAT3(A)

-

1.

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

2.

Inductance: Tested at 1MHz, 0.1 VRMS.

-

3.

ISAT: DC current through the winding to cause a 10% (typ) drop in inductance.

-

4.

IDC: DC current through the winding to cause a 40°C (typ) temperature rise at 25°C ambient. PCB layout, trace thickness and width, airflow and proximity to other devices will affect the temperature rise.

-

5.

Flammability Standard: Meets UL 94V-0.

-

6.

PACKAGING

- Reel Diameter: 13″

- Reel Width: 24mm

- Pieces/Reel: 600

-

7.

Specifications subject to change without prior notice.