- Home

- Inductors

- SMT High Current Inductors

- LP02-3 Series

LP02-3 Series

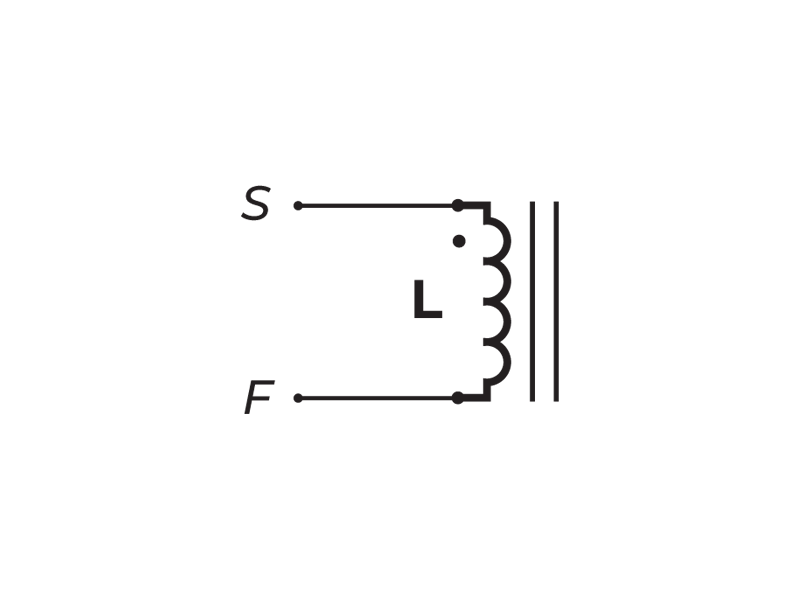

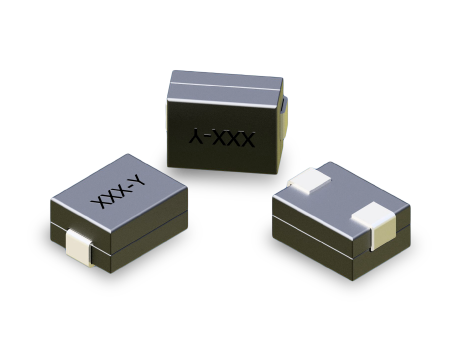

High-Current, Low-Inductance, SMT One-Turn Inductors

The LP02-3 Series high-current SMT one-turn inductors deliver low-inductance, high-current performance for VRMs, POL converters, and high-frequency switching supplies. With inductance values from ~90 nH to ~350 nH and saturation current ratings up to 72 A, the series supports efficient, stable power delivery under heavy load — ideal for server, desktop, and embedded power modules.

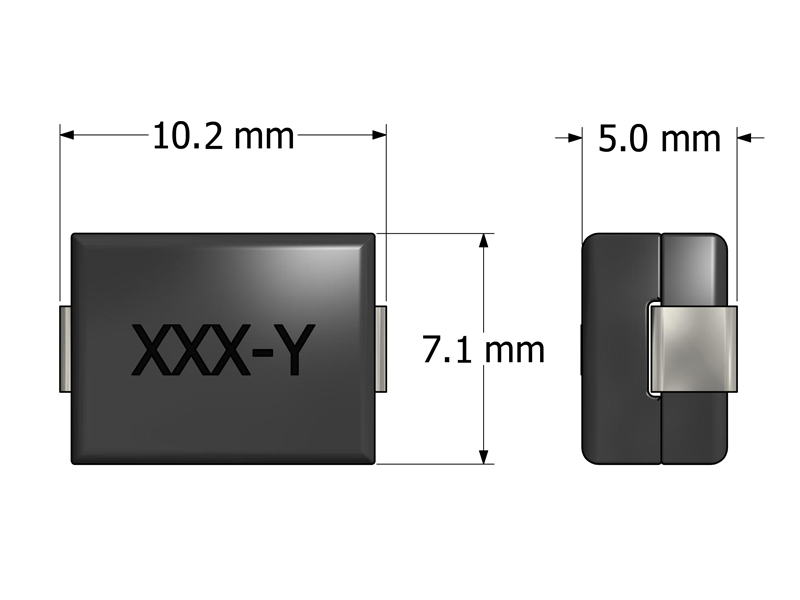

Optimized for high-frequency switching up to 1 MHz, LP02-3 offers a compact footprint of 10.2 × 7.1 mm and a low profile of 5.0 mm height, enabling dense PCB layouts while maintaining strong current capacity and thermal performance. Its SMT package supports pick-and-place automated assembly for efficient mass production.

Key Features

- Compact footprint 10.2 × 7.1 mm and height 5.0 mm for dense layout

- Inductance range 90–350 nH for low-impedance, high-current filtering

- Saturation capability up to 72 A for demanding VRM and converter loads

- Low-DCR winding for high efficiency and minimal thermal loss

- Supports up to 1 MHz switching frequency for high-speed converters

- SMT package enabling automated pick-and-place assembly

- Design verified by leading IC manufacturers

APPLICATIONS

- Voltage Regulator Modules (VRMs) for CPUs, GPUs, SoCs

- Point-of-Load (POL) converters in servers, notebooks, and compact devices

- High-frequency synchronous buck or boost DC/DC converters

- Compact power modules on space-constrained PCBs

- High-current power rails in telecom, industrial, and embedded power systems

- Voltage Regulator Modules (VRMs) for CPUs, GPUs, SoCs

- Point-of-Load (POL) converters in servers, notebooks, and compact devices

- High-frequency synchronous buck or boost DC/DC converters

- Compact power modules on space-constrained PCBs

- High-current power rails in telecom, industrial, and embedded power systems

Electrical Specifications @ 25°C - Operating Temperature Range1: -40°C to +130°C

Part Number

Inductance2

(nH, ±15%)

DCR3

(mΩ, ±10%)

ISAT4 (A)

IDC5 (A)

Part Number

Inductance2 (nH, ±15%)

DCR3

(mΩ, ±10%)

ISAT4 (A)

IDC5 (A)

-

1.

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

2.

Inductance: Tested at 1MHz, 0.1 VRMS.

-

3.

Tighter DCR tolerances available. Contact ICE for more details.

-

4.

ISAT: DC current through the winding to cause a 15% (typ) drop in inductance.

-

5.

IDC: DC current through the winding to cause a 40°C (typ) temperature rise at 25°C ambient. PCB layout, trace thickness and width, airflow and proximity to other devices will affect the temperature rise.

-

6.

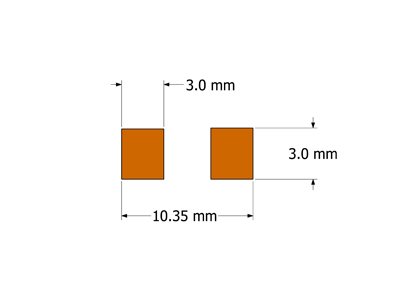

PACKAGING

- Reel Diameter: 13″

- Reel Width: 16mm

- Pieces Per Reel: 800

-

7.

Specifications subject to change without prior notice.