-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

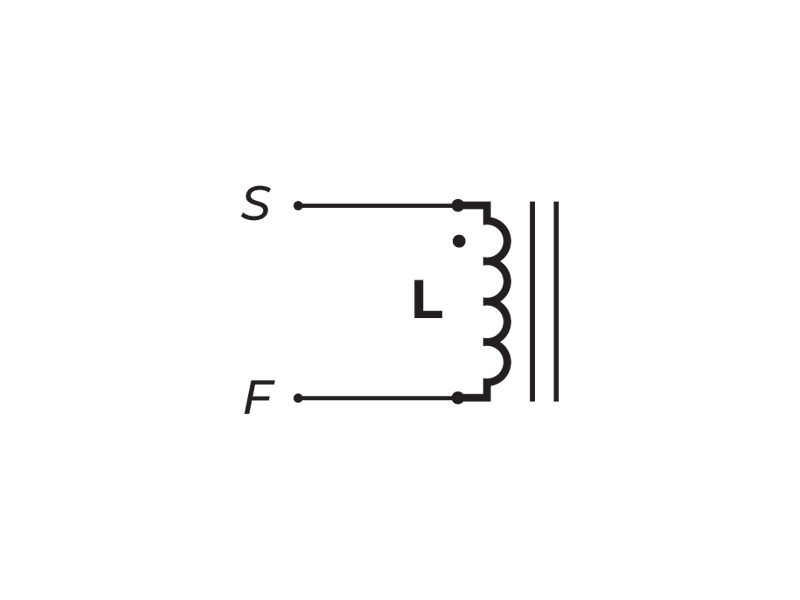

Inductance: Tested at 1MHz, 0.1 VRMS.

-

Tighter DCR tolerances available. Contact ICE for more details.

-

ISAT: DC current through the winding to cause a 15% (typ) drop in inductance.

-

IDC: DC current through the winding to cause a 40°C (typ) temperature rise at 25°C ambient. PCB layout, trace thickness and width, airflow and proximity to other devices will affect the temperature rise.

-

PACKAGING

- Reel Diameter: 13″

- Reel Width: 16mm

- Pieces/Reel: 1000

-

Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

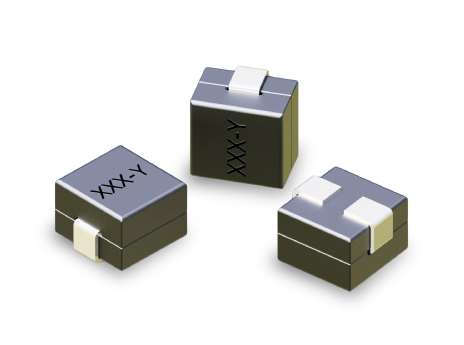

What current and inductance options are provided by the LP02-1S Series?

LP02-1S offers very low-inductance SMT inductors with inductance values around 50–85 nH and saturation-current (ISAT) ratings up to 85 A, giving designers high current capacity in a compact form factor suitable for POL and VRM applications.

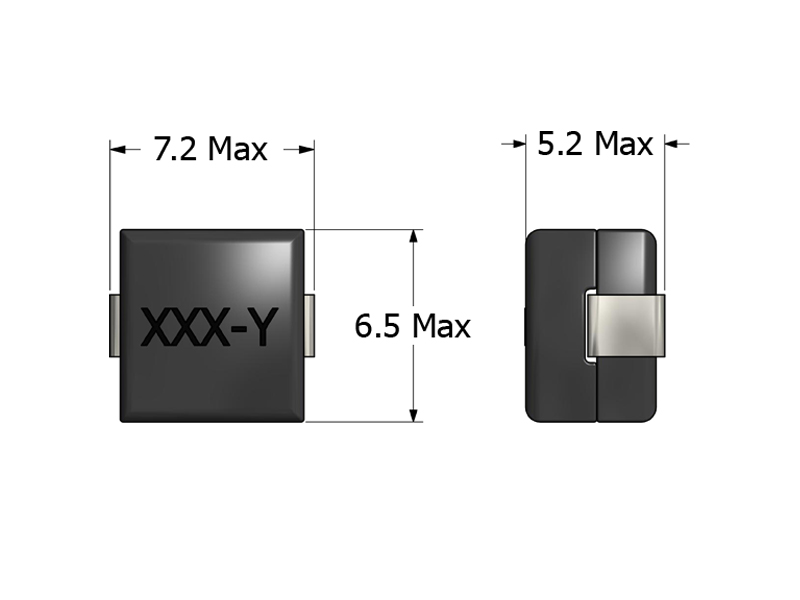

What footprint and package height does LP02-1S use and why is this important?

The maximum footprint is 7.2 × 6.5 mm with a height of up to 5.2 mm, making LP02-1S ideal for high-density PCB layouts and automated SMT assembly — important for compact power supplies and board-level DC/DC converters.

What switching-frequency range can LP02-1S handle reliably?

The series supports high-speed switching up to 1 MHz, making it appropriate for modern synchronous buck converters and high-frequency POL regulators where fast transient response and compact layout matter.

How does LP02-1S manage heat under continuous load?

LP02-1S parts are rated for a defined “IDC” current (e.g. 50 A) corresponding to a temperature rise (as specified in the datasheet). Thermal performance depends on PCB layout, trace width, copper area, and airflow — good layout and proper copper cooling are essential to maintain reliability under continuous load.

What trade-offs exist when using a one-turn SMT inductor like LP02-1S?

Because LP02-1S is a low-inductance, high-current inductor, it’s optimized for power-rail filtering and output smoothing in high-current, high-frequency converters — but it is not suited for applications requiring high inductance, large energy storage, or low-frequency filtering.

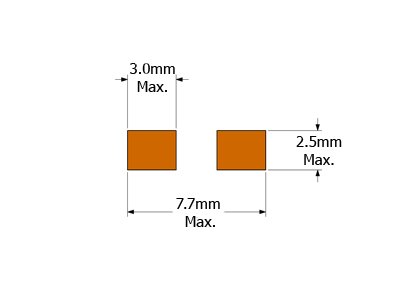

What layout considerations apply when using LP02-1S on a PCB?

To maximize performance, designers should ensure wide copper traces, adequate via count for current paths, and sufficient copper for heat dissipation. Poor layout can undermine the inductor’s current rating and lead to thermal issues even if the inductor itself is rated adequately.

When should designers choose LP02-1S over larger or multi-turn inductors?

Use LP02-1S when PCB space is constrained, automated SMT assembly is required, and the application demands high current with relatively low inductance — such as POL converters, VRMs for CPUs/GPUs/SoCs, or compact DC/DC modules.

How does LP02-1S behave under DC bias and ripple current?

Because of its design and low-inductance value, LP02-1S remains stable under DC bias typical in VRMs and output filters. It handles ripple current and fast switching well when matched appropriately to load and layout conditions.

Is LP02-1S suitable for very high-power applications (>100 A)?

LP02-1S is optimized up to its specified saturation current (85 A), but for loads significantly above that — or if sustained high currents are expected — a larger or multi-turn inductor with a higher current rating may be more appropriate.

What kinds of applications fit best with LP02-1S?

LP02-1S is ideal for point-of-load (POL) regulators, VRMs, high-frequency DC/DC converters, embedded power modules, telecom or networking power rails, and any compact power-supply designs where high current and small footprint are critical.