ITP Series

High-Current Through-Hole Toroidal Inductors

The ITP Series high-current toroidal inductors provide robust energy-storage and filtering performance for demanding power-conversion platforms. Offering inductance values from 10 µH to 1000 µH and current ratings up to 20 A, the series delivers low DCR, stable behavior under DC bias, and efficient operation across a wide range of converter and filter topologies. Its toroidal construction provides inherent self-shielding and low radiated noise while maintaining compact dimensions for high-density layouts.

Built on powdered-iron cores with a soft-saturation characteristic, the ITP Series maintains predictable inductance roll-off at elevated current levels, supporting reliable operation in buck/boost stages, SMPS architectures, and EMI-sensitive systems. The through-hole package ensures mechanical stability and consistent electrical performance in industrial, telecom, and embedded environments that require a dependable high-current inductor.

Key Features

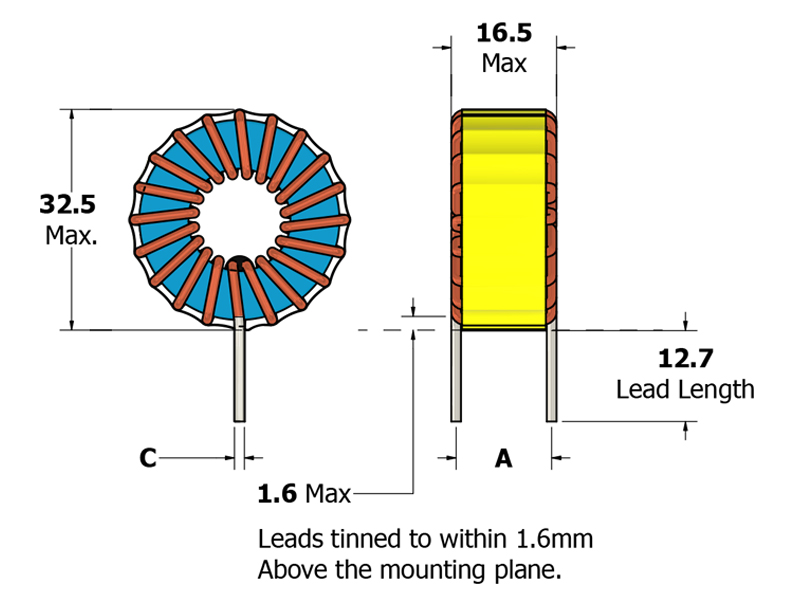

- PCB footprint up to 32.5 × 16.5 mm max, height up to 32.5 mm max

- Inductance range from 10 µH to 1000 µH for storage and filtering flexibility

- Rated currents up to 20 A with low DCR for high efficiency

- Powdered-iron toroidal core providing soft, gradual saturation under DC bias

- Self-shielding toroidal geometry minimizing EMI radiation

- Through-hole construction offering robust mechanical stability in power designs

APPLICATIONS

- Buck/boost converters and general DC/DC power stages

- SMPS energy-storage and output-filter inductors

- EMI-suppression chokes in noise-sensitive electronics

- Industrial and telecom power rails requiring high-current inductors

- Embedded systems needing stable magnetics under load

- Buck/boost converters and general DC/DC power stages

- SMPS energy-storage and output-filter inductors

- EMI-suppression chokes in noise-sensitive electronics

- Industrial and telecom power rails requiring high-current inductors

- Embedded systems needing stable magnetics under load

Electrical Specifications @ 25°C - Operating Temperature Range1: -40°C to +105°C

Part Number

L @ 0A 2

(uH, +/-15%)

IDC 3

(A)

L @ IDC 2

(uH, +/-15%)

DCR

(Ω, Max.)

K Factor 4

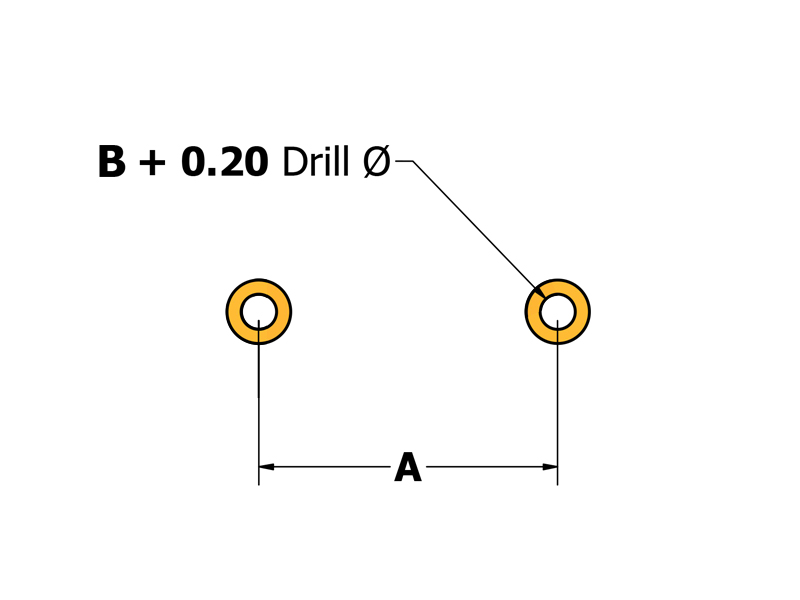

Dim A

(mm, Nom.)

Dim B

(mm, Nom.)

Part Number

L @ 0A 2

(uH, +/-15%)

-

1.

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

2.

Inductance: Tested at 10kHz, 30 – 301 mVRMS, Series

-

3.

Idc: Current to cause 30°C max temperature rise.

-

4.

DC Bias Inductance Calculation:

-

5.

All components have passed the ICE Reliability Standard testing. For further information, please contact ICE directly.

-

6.

PACKAGING

-

Pieces/Box: 30

-

Boxes/Carton: 12

-

Pieces/Carton: 360

-

-

7.

Specifications subject to change without prior notice.