-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

Drive Inductance: Tested at 100kHz, 0.1 VRMS.

-

SRF: Values are for reference only.

-

Flammability Standard: Meets UL 94V-0.

-

ET Product: The maximum ET is based upon a flux density of 3300 Gauss at 25°C. Derate the E-T product rating by 20% for operation at 100°C.

ET = EP/2f

Where as, EP = Primary Voltage (V) f = Frequency (Hz) -

Hi-Pot Rating (Gate:Gate): 1500 VDC

-

Suitable for bipolar applications only.

-

PACKAGING

-

Reel Diameter: 13″

-

Reel Width: 32mm

-

Pieces/Reel: 400

-

-

Compliance & Solutions:

-

Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

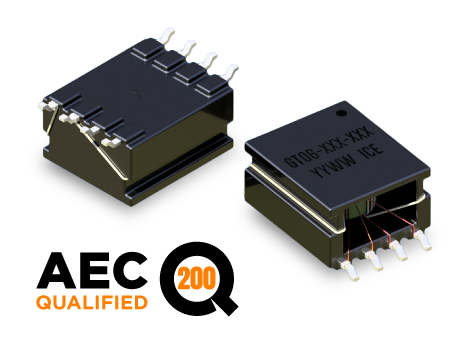

What makes the GT06 Series unique in the market?

The GT06 Series is one of the few SMT gate drive transformers that offers AEC-Q200 automotive qualification combined with a massive 12.5 mm creepage distance, bridging the gap between compact SMT parts and large high-voltage THT parts.

Why is the 12.5 mm creepage distance important for EVs?

In Electric Vehicles (EVs), high voltages combined with potential dust or moisture require larger spacing to prevent electrical arcing. The 12.5 mm creepage ensures safety compliance without needing a larger through-hole component.

How does the GT06 Series’ turns ratio affect the gate-drive voltage delivered?

GT06 transformers are available in 1:1:1 and 1:2.5:2.5 turns ratios. The 1:2.5:2.5 ratio effectively increases the voltage delivered to the gate relative to the driver’s primary, allowing higher gate voltages without changing the driver supply. Choosing the proper ratio helps optimize gate overdrive for SiC, IGBT, or MOSFET devices based on their gate voltage requirements.

What role does drive inductance play in GT06’s waveform performance?

Drive inductance ranges significantly across variants (from about 162 µH to 2000 µH). Higher inductance improves low-frequency performance and pulse stability but requires more magnetizing energy, while lower inductance supports faster edges with less energy stored. Matching inductance to the driver and switch improves pulse fidelity.

How does leakage inductance influence switching performance?

GT06 leakage inductance (typical maximum from ~240 nH to ~470 nH depending on part) affects how tightly the magnetic field couples between windings. Lower leakage supports cleaner waveforms with less ringing, while higher leakage can introduce voltage overshoot and waveform distortions.

What is the significance of the E-T product for GT06 in gate-drive design?

Each GT06 variant has an ET product rating (e.g., 49 V-µs to 100 V-µs). This defines the maximum Volt-microsecond product of the transformer core. For low switching frequencies or high primary voltages, the ET limit must be respected — otherwise the core can saturate, causing waveform distortion and loss of primary inductance.

Why does GT06 specify a frequency range of ~40 kHz to 350 kHz?

This range identifies where the transformer maintains effective coupling and low loss. Operation below this range risks distortions from insufficient magnetizing inductance, high core losses and possible core saturation, and above it, winding parasitics and distortion due to self-resonance.

How should the creepage/clearance specification influence PCB layout?

GT06’s 12.5 mm creepage and clearance rating supports robust isolation in high-voltage environments like EV/HEV inverters or battery management systems. PCB layout should maintain this spacing between drive and gate circuits to avoid creepage-related failures and ensure safety compliance in automotive and industrial designs.

What practical impact does the DCR (winding resistance) have on driver loading?

Primary and secondary winding DCR values (e.g., 720 mΩ, 1430 mΩ, etc.) affect how much current the transformer draws from the driver. Lower DCR reduces resistive loss and driver stress, while higher DCR increases dissipation and can affect driver thermal performance. The right variant balances DCR with inductance and waveform needs.

How does the GT06 isolation rating support system safety?

The 3750 VAC isolation capability enables safe separation between control electronics and high-power switching nodes. This protects low-voltage circuitry from common-mode voltage spikes and simplifies barrier design in safety-critical power converters.