-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

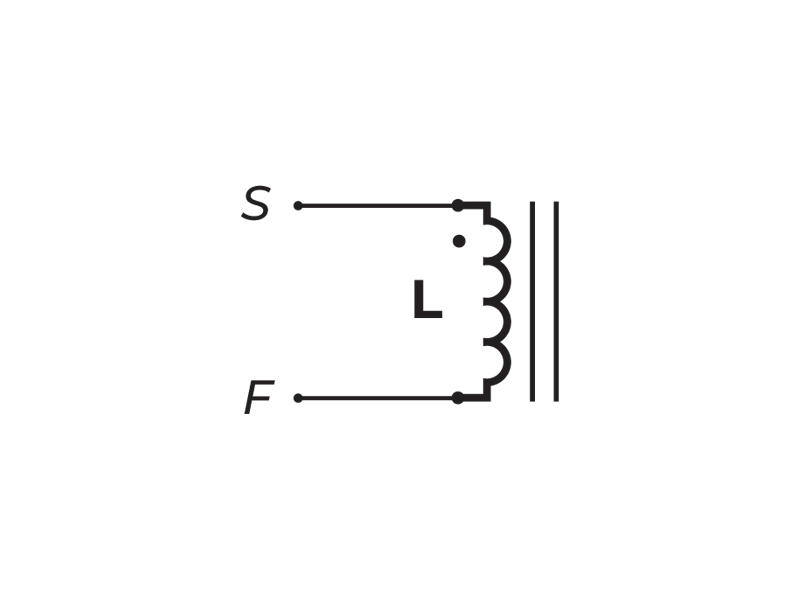

Inductance: Tested at 100kHz, 1 VRMS, Series.

-

ISAT: DC current through the winding to cause a 10% (typ) drop in inductance.

-

IDC: DC current through the winding to cause a 40°C (typ) temperature rise at 25°C ambient.

-

Flammability Standard: Meets UL 94V-0.

-

SRF: Values are for reference only.

-

Packaging

- Pieces/Tray: 60

- Trays/Box: 6

- Pieces/Box: 360

-

Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

What inductance variants are offered in 1D23A, and how should I pick one?

1D23A offers 10 µH, 15 µH, 22 µH, and 33 µH (±20%). Lower values give lower impedance and faster response (useful when switching or transients are involved); higher values provide stronger filtering of ripple and output noise in power supplies or audio output stages.

What current ratings apply to 1D23A, and what does that imply for application use?

Depending on variant, 1D23A's saturation current (Iₛₐₜ) ranges from ~10.4 A (33 µH) to ~37.8 A (10 µH), but the effective continuous DC current (IDC) for a 40 °C temp rise is ~9.4 A — making it suitable for moderate-current audio outputs or low-current DC rails, not for heavy high-current switching power rails.

What is the significance of SRF range (10.9–26.8 MHz) in 1D23A?

The reference SRF range indicates where the inductor transitions from inductive to capacitive behavior. Since SRF is well above audio and low-frequency switching ranges, 1D23A remains reliably inductive for intended use — preserving filter performance and avoiding resonance-related issues.

How does shielding improve inductor performance in audio or mixed-signal applications?

Shielding reduces magnetic leakage and radiated EMI, which helps prevent noise coupling into audio or signal lines, and improves system EMI compatibility — particularly important in audio amplifiers, mixed-signal boards, or dense electronic assemblies.

When should I avoid using 1D23A?

Avoid using 1D23A in high-current, high-frequency switching converters (e.g. >100 kHz switching with high ripple) — due to its relatively high inductance, limited continuous current rating, and low-frequency optimization.

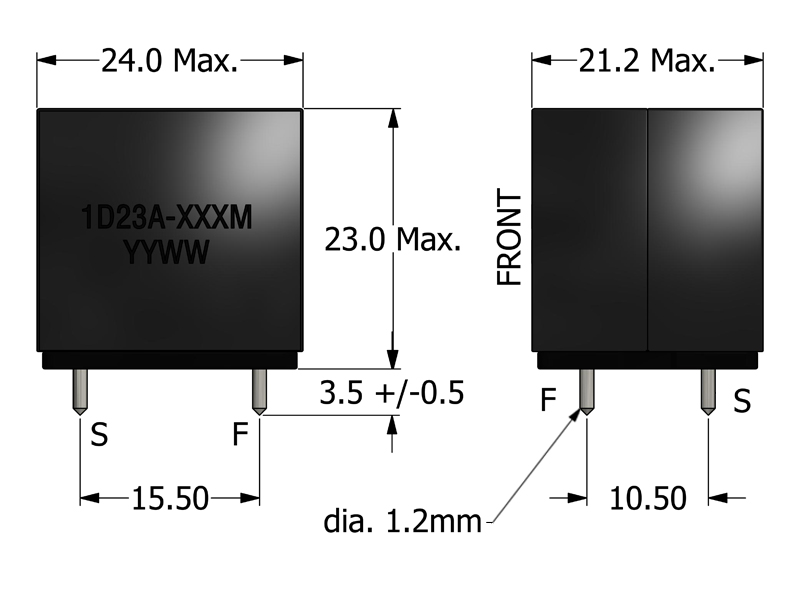

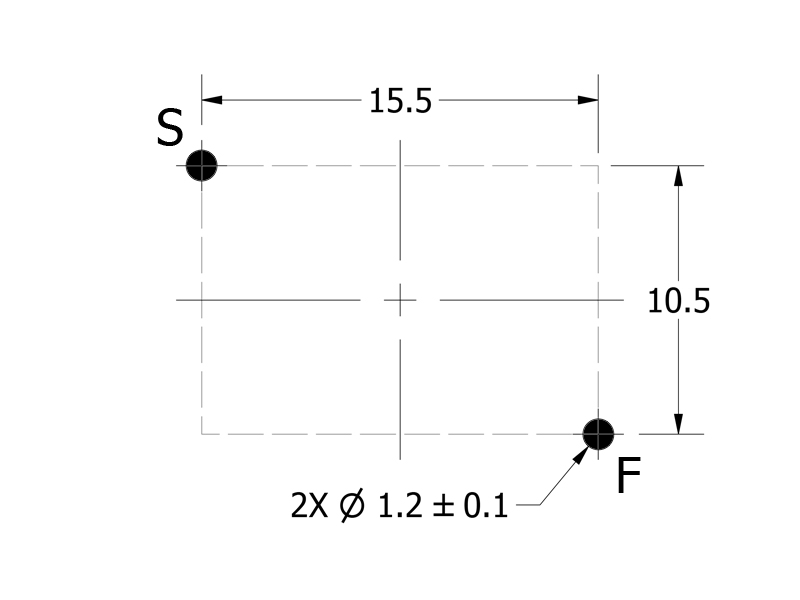

What are layout and mounting considerations for 1D23A integration?

Because it is a through-hole part, allow adequate PCB footprint, ensure secure solder joints, and provide sufficient copper trace width or plane for current paths. For power-supply rails, plan for thermal dissipation and consider decoupling capacitors to handle ripple.

What bias or ripple current considerations must be accounted for?

High ripple currents may increase core or copper losses; designers should ensure that the inductance value and inductor’s current rating suit anticipated load, and add output capacitance if needed to smooth ripple or transients.

Can 1D23A be used in battery-powered or portable devices?

Yes — for low-frequency filtering or smoothing tasks where mechanical robustness and EMI control matter. But consider current draw, footprint, and height before selecting, especially in compact mobile devices.

Is 1D23A compatible with surface-mount or only through-hole assembly?

1D23A is through-hole only, offering secure mechanical anchoring and better reliability under mechanical or thermal stress compared to many SMT inductors.

What design parameters should I check before choosing a 1D23A variant?

Evaluate required inductance, current (steady and peak), ripple or noise level, footprint/height constraints, EMI requirements, and whether filter or rail-stabilization is the design goal.