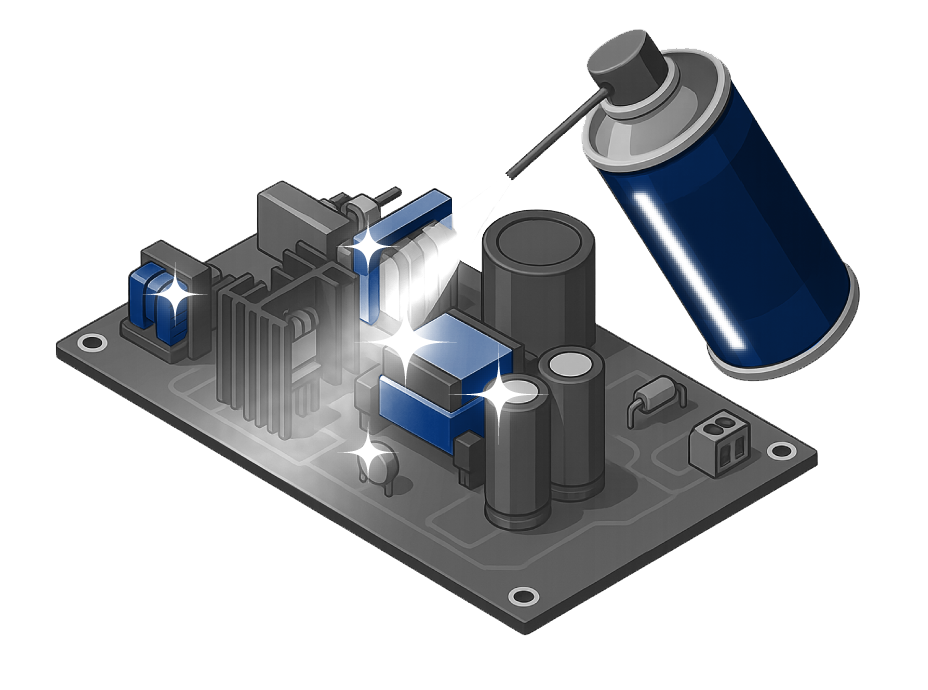

ICE Component Washability and PCB Cleaning Compatibility

Component cleaning robustness is a key design consideration for modern electronics, as improper cleaning can lead to residue buildup, corrosion, or signal integrity issues that compromise long-time reliability. Recognizing this, ICE Components designs and engineers its parts to be highly resilient, fully capable of withstanding the standard PCB cleaning processes used in high-volume electronic assembly.

This built-in robustness includes compatibility with both common aqueous (water-based) and solvent-based cleaning systems. However, while our products themselves are not inherently sensitive to most qualified cleaning agents, the overall success of any cleaning protocol is not guaranteed by the component alone. The effectiveness and safety of your procedure depend on the complex interaction of multiple factors within your specific production environment, including:

• The type and concentration of cleaning chemicals;

• Mechanical agitation or spray pressure;

• Exposure time and temperature;

• Number of rinse and drying cycles;

• PCB layout and component density.

For aqueous and semi-aqueous systems, ensure that residues are fully removed and drying is complete to prevent long-term reliability issues. ICE Components does not certify compatibility with specific cleaning systems or chemistries. Instead, we encourage customers to validate cleaning protocols under actual production conditions. If your process involves solvents or additives outside typical industry use, we suggest conducting localized testing to confirm material stability and performance.

For reference, ICE Components evaluates cleaning resilience using applicable standards such as MIL-STD-202 Method 215.

Need help integrating our components into your cleaning workflow or reliability testing? Our technical team is ready to assist.