-

Operating Temperature Range: The combination of ambient temperature and temperature rise.

-

Inductance: Tested at 100kHz, 0.1 VRMS, 0ADC Bias.

-

ISAT: DC current through the winding to cause a 15% (typ) drop in inductance.

-

IDC: DC current through the winding to cause a 40°C (typ) temperature rise at 25°C ambient.

-

Flammability Standard: Meets UL 94V-0.

-

Packaging

- Pieces/Tray: 130

- Trays/Box: 16

- Pieces/Box: 2080

-

Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

What makes the I02 Series suitable for high-current VRM and POL applications?

The combination of low DCR windings, powdered-iron core stability, and saturation currents up to 60 A allows I02 inductors to maintain low loss and stable inductance during rapid load transients common in VRM and POL regulators.

How does the powdered-iron core improve performance under DC bias?

Powdered-iron provides a distributed air-gap effect, resulting in soft, gradual saturation rather than abrupt inductance collapse. This ensures predictable behavior at high load currents and reduces the risk of voltage droop in tightly regulated converters.

Does the I02 Series offer lower DCR than similar toroidal designs?

Yes. The optimized winding geometry results in lower DCR compared to typical toroidal inductors of similar inductance and size, improving overall efficiency and reducing thermal rise.

How stable is inductance across operating current and temperature?

Thanks to the powdered-iron core, inductance remains stable under heavy DC bias and across typical power-supply temperature ranges, making it suitable for compact, thermally constrained VRM layouts.

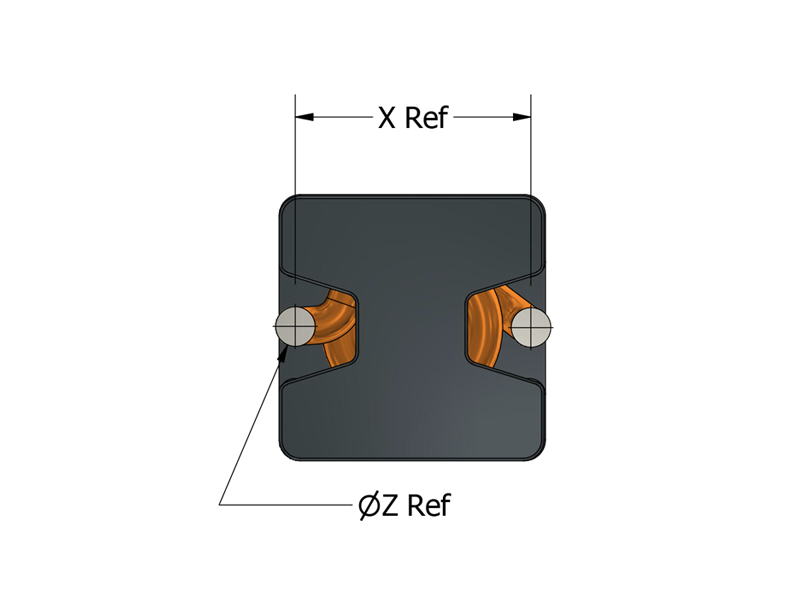

What mechanical advantages does the through-hole construction provide?

Through-hole terminations offer strong mechanical anchoring, beneficial in high-current or vibration-prone environments such as industrial controllers, server power boards, and telecom platforms.

Why is a low-profile form factor important for I02 applications?

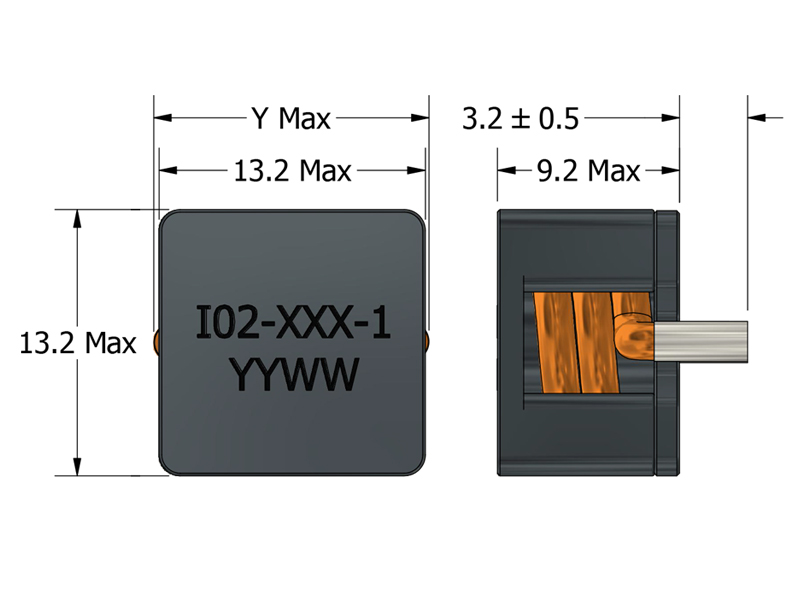

The compact 16.0 × 13.2 mm footprint and 9.2 mm max height allow the I02 Series to fit into dense VRM modules, CPU socket areas, and compact DC/DC converter footprints without obstructing airflow or thermal pathways.

How should I select the correct inductance value for my design?

Lower inductance values provide faster transient response and higher saturation capability, while higher inductance values reduce ripple current. Selection should consider switching frequency, ripple limits, and required response time for the regulator.

What determines the saturation current rating for each I02 part?

Saturation current is defined by the DC bias that causes approximately a 15% inductance drop. Core size, material, and winding geometry all influence this rating, with higher values indicating better overload and transient tolerance.

Is the I02 Series appropriate for EMI-sensitive applications?

Yes. Although not a shielded SMD structure, the compact magnetic path and stable DC-bias characteristics help reduce stray flux and limit noise coupling in VRM and DC/DC converter environments.

What factors differentiate I02 from other high-current THT inductors?

Key differentiators include its lower DCR, soft-saturation powdered-iron core, high saturation current ratings, and compact mechanical envelope—all optimized for modern power stages requiring efficiency, reliability, and small footprint.