-

Operating Temp. Range: The combination of ambient temperature and temperature rise.

-

Inductance: Tested at 1MHz, 0.1 VRMS.

-

ISAT: DC current through the winding to cause a 15% (typ) drop in inductance.

-

IDC: DC current through the winding to cause a 40°C (typ) temperature rise at 25°C ambient. PCB layout, trace thickness and width, airflow and proximity to other devices will affect the temperature rise.

-

Flammability Standard: Meets UL 94V-0.

-

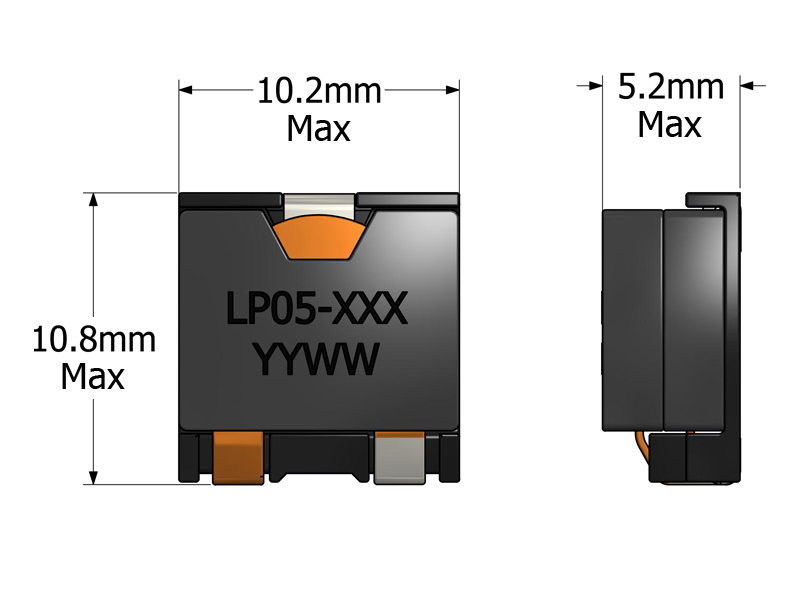

Height: 5.7mm Max.

Length: 11.0mm Max. -

PACKAGING

- Reel Diameter: 13″

- Reel Width: 24mm

- Pieces/Reel: 700

-

Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

How does the LP05 perform under high ripple current conditions in real-world use?

Under ripple current stress, LP05’s low-DCR flat-wire winding helps limit conduction losses and thermal rise. Still, actual ripple handling depends heavily on PCB layout, trace width, and copper pour — insufficient copper area or poor layout can increase temperature and degrade efficiency even if the inductor itself is within spec.

What layout and thermal-management practices maximize LP05 reliability?

Use sufficiently wide copper traces or pours, add thermal vias if possible, and avoid placing high-heat components close to the inductor. Good airflow or heat-sinking helps prevent thermal drift or saturation under continuous high current or sustained load.

How does DC bias affect inductance stability and ripple performance of LP05?

As DC load current approaches ISAT, the core begins to saturate, reducing effective inductance and lowering impedance — this increases ripple current and reduces filtering effectiveness. Designs should include margin between typical load and ISAT to preserve performance under peak loads.

What trade-offs come with the low-DCR, high-current, low-inductance design of LP05?

The LP05 offers high current capability and efficiency, but its inductance values are relatively low (100–1300 nH). It is best suited for high-current, low-impedance power rails; for tasks needing larger energy storage or low-frequency filtering, a different inductor type may be preferable.

How does LP05 behave under transient or surge load conditions?

It can tolerate short-duration transient currents above nominal load if thermal and saturation margins are respected. However, frequent surges near ISAT or prolonged high-current pulses can lead to core heating, increased loss, and reduced lifespan. Adequate derating and thermal margin are advised.

Why is copper trace design especially important when using LP05 in multi-phase or parallel converter designs?

Because each inductor sees high current, uneven or narrow trace widths, asymmetric layouts, or varying copper thicknesses can cause current imbalance, higher conduction losses, or thermal hotspots — undermining converter balance and reliability.

How should designers verify LP05 behavior in simulation models?

Use real-world parameters: include actual DCR, DC-bias inductance derating, ripple current loss, and thermal resistance. Avoid assuming ideal inductor behavior — realistic modeling helps predict efficiency, temperature rise, and ripple under load.

Under what conditions might LP05 become a less optimal choice?

When the application demands high energy storage, low switching frequency, or substantial low-frequency filtering — conditions where a higher-inductance inductor with better energy storage capability would perform better than LP05.

What mechanical or environmental factors can affect LP05 long-term reliability?

Repeated thermal cycling, high ambient temperature, or poor solder-joint quality can accelerate wear. Maintaining proper soldering standards and thermal margin, plus ensuring stable operating conditions, helps ensure longevity.

How does stray coupling or layout proximity to switching nodes affect LP05 performance?

Because LP05 may be placed near high-di/dt switching elements, careful layout is needed to prevent EMI coupling or unwanted noise on adjacent traces. Keep sensitive nodes away, use proper ground planes, and ensure minimal loop area for switching paths.