-

Operating Temperature Range: The combination of ambient temperature and temperature rise.

-

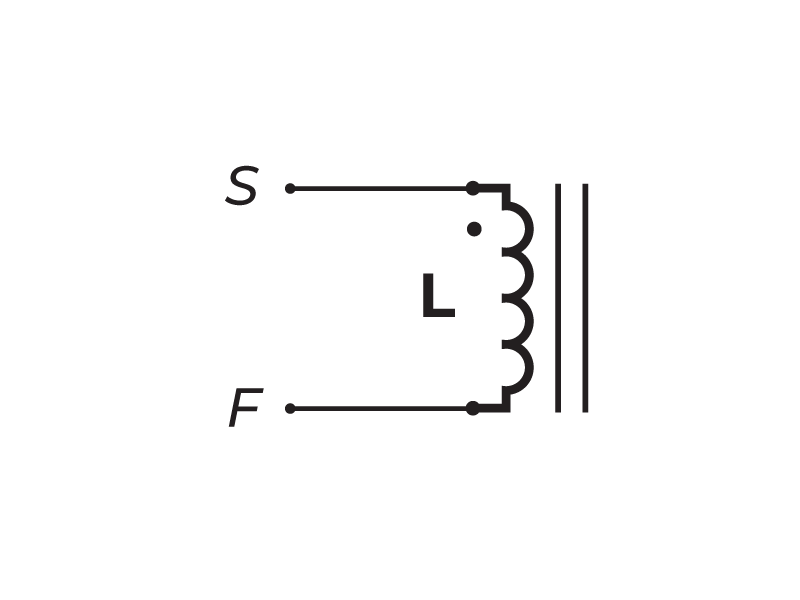

Inductance: Tested at 100kHz, 0.1 VRMS, 0ADC Bias.

-

ISAT: DC current through the winding to cause a 30% (typ) drop in inductance.

-

IDC: DC current through the winding to cause a 50°C (typ) temperature rise at 25°C ambient.

-

Flammability Standard: Meets UL 94V-0.

-

Insulation System Requirements: Meets Class F (155°C).

-

Packaging

- Pieces/Tray: 120

- Trays/Box: 10

- Box: 1200

-

Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

What current and inductance options are available in the I03 Series?

The I03 Series offers inductance values of 1.4 µH, 3.0 µH, and 5.6 µH. Each value corresponds to specific DCR, saturation current, and thermal current ratings, allowing designers to choose the option that best fits their ripple and load requirements.

What does “saturation current” (ISAT) mean for I03, and how does it affect design?

ISAT is the current level at which inductance drops by about 30%. The I03’s 1.4 µH variant supports up to 50 A before significant inductance reduction, ensuring reliable operation in compact VRMs and high-current converter stages.

How does DC bias affect inductance stability in I03 inductors?

The powdered-iron core and optimized winding maintain consistent inductance under heavy DC bias. This stability ensures predictable performance in high-current rails and reduces ripple variation across load conditions.

What thermal behavior can be expected from I03 under continuous load?

Each I03 rating defines the current that produces roughly a 50 °C temperature rise. Staying within this limit keeps the inductor in a safe thermal range. The through-hole package improves heat dissipation for long-term reliability in industrial and server environments.

Is I03 suitable for high-frequency switching converters?

I03 is intended for typical DC/DC converter frequencies, providing stable inductance and strong DC-bias performance. It is not optimized for MHz-range switching or high-dv/dt gate-drive circuits.

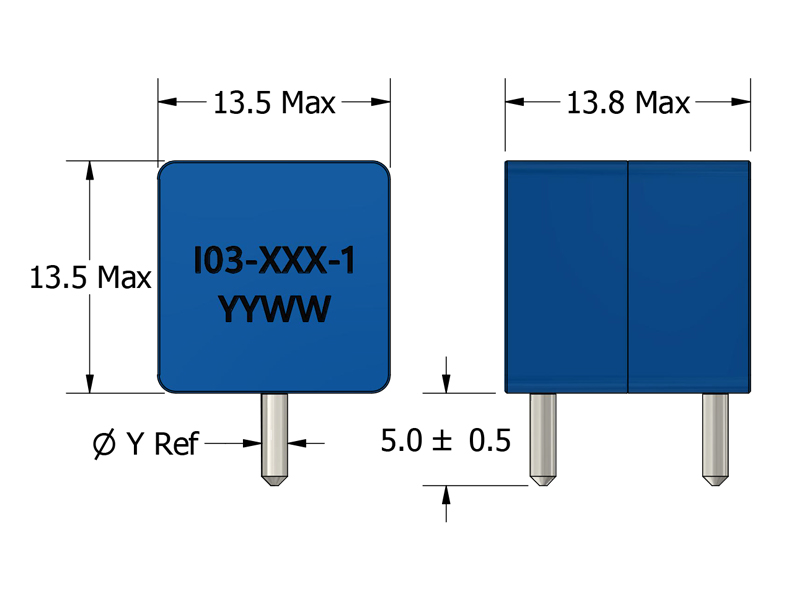

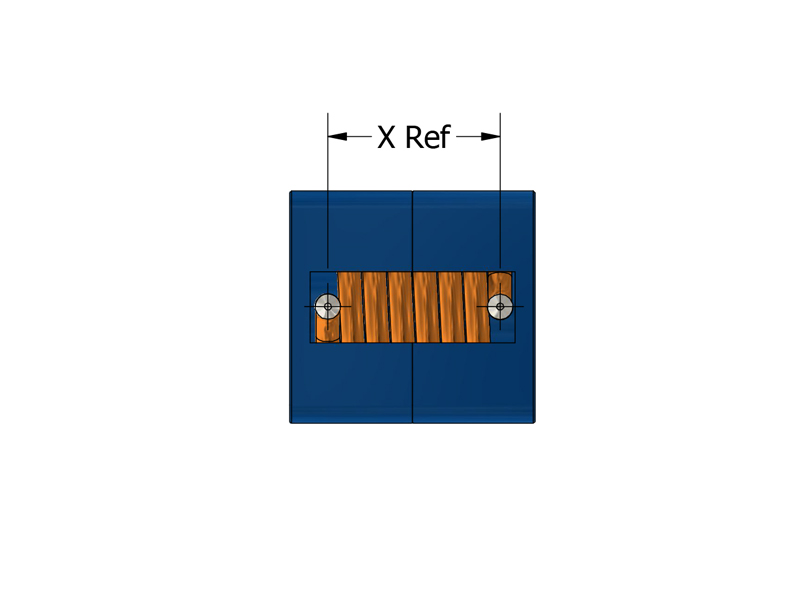

What are the mechanical and PCB-layout considerations when using I03?

The package footprint is compact (max ~13.5 × 13.8 mm), and the through-hole leads provide strong mechanical anchoring. Designers should ensure adequate copper area for current handling and thermal spreading.

How do I choose the right I03 variant for a given application?

Select an inductance that meets ripple requirements, ensure ISAT exceeds expected peak current, and verify IDC meets continuous load conditions. DCR and core losses should align with efficiency and thermal budgets.

Can I combine I03 inductors in parallel or series for special requirements?

It is possible, but parallel combinations require careful consideration of current sharing and ripple distribution. Using a higher-current single model is often more reliable than paralleling multiple inductors.

What types of applications are best served by I03?

The I03 Series is ideal for point-of-load regulators, VRMs, high-current DC/DC converters, embedded power rails, and industrial systems requiring stable inductance under DC bias.

Are there limitations to watch out for when using I03 inductors?

The I03 offers low inductance values and is not intended for low-frequency filtering. As with all inductors, operation near saturation current reduces inductance, so adequate current margin should be included in the design.